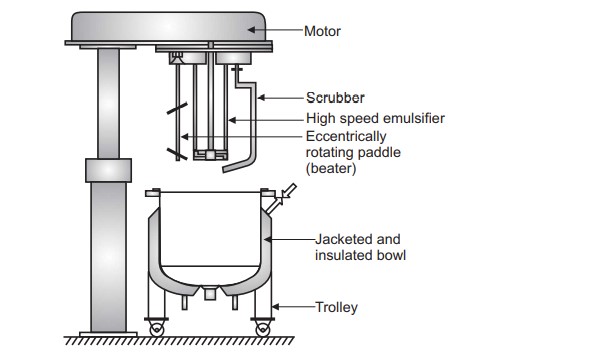

Planetary Mixer

The planetary mixer is a high-shear mixer and is available with a variable speed drive. It is suitable for mixing ointments, inks, sauces, pastes, and foam used in the pharmaceutical, food, chemical, and allied industries. Principle of Planetary Mixer The principle of planetary mixer is based on the rotation of planetary blades on their own … Read more