There are three popular shapes of twin shell blenders (also known as a tumble blender), namely; the V-blender, the double cone blender, and the slant cone blender. Tumble type blending is most suited for products of uniform particle size and density, and where requirements for fast, thorough cleaning are desirable for sanitary applications. The V-blender is one of the most commonly used tumblers as they offer both short blending times and efficient blending.

Table of Contents

Principle of twin shell blender

Tumble blenders works upon the action of gravity to cause the powder to cascade within a rotating vessel. The primary mechanism of blending in a V-blender is diffusion. Diffusion blending is characterized by the small scale random motion of solid particles. Blender movements increase the mobility of the individual particles and thus promote diffusive blending. Diffusion blending occurs where the particles are distributed over a freshly developed interface. In the absence of segregating effects, the diffusive blending leads to a high degree of homogeneity.

Construction of twin shell blender

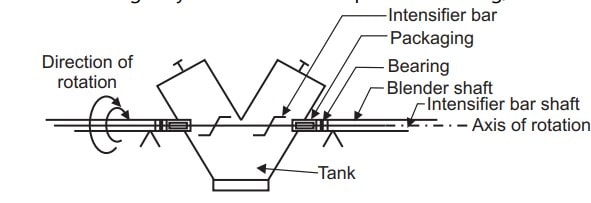

The V-blender is made of two hollow cylindrical shells joined at an angle of 75° to 90°. A tank formed by two V-shaped cylinders turning around a horizontal shaft ensures a perfect and quick homogenization of the components of the mix. The product enters and exits at the tip of the V easily and without dust. Liquid injection facility may be provided to obtain a granulation of the pre-mixed powder, a coating of the granules or for an automatic cleaning system. A V-blender can be provided with high-speed intensifier bars (or lump breakers) running through trunnion into the vessel, along with spray pipes for liquid addition. The intensifiers disintegrate agglomerates in the charge material or those formed during wet mixing. A schematic drawing of the V-blender with the intensifier bar is shown in Figure below. The V-blender is offered in many sizes with volume ranging from 0.25 to 100 ft3 and can be customized with optional features such as vacuum capability, intensifier bar, spray nozzles, heating/cooling jacket, and explosion-proof motor and built-in controls. The heavy-duty models capable of blending very dense materials up to 90 – 100 kg/ft3 are also available.

Working of twin shell blender

The charging of material into the V-blender is through either of the two ends or through the apex port. As the V-blender tumbles, the material continuously splits and recombines, with the mixing occurring as the material freely and randomly falls inside the vessel. The repetitive converging and diverging motion of material combined with increased frictional contact between the material and the vessel long straight inner wall surface result in gentle and homogenous blending. In case of monodisperse powders there is no mechanism involved in movement of the powders across the line of symmetry of the blender. For such materials, care must be taken to load each side of the blender equally to ensure desired homogeneity of blends. Blending efficiency is affected by the volume of the material loaded into the blender. The recommended fill-up volume for this blender is 50 to 60% of the total blender volume. For example, if the fill material in the blender is increased from 50% of the total volume to 70% of the total volume, the time required for homogenous blending may be doubled. Blender speed may also be a key to mixing efficiency. At lower blender speeds, the shear forces are low. Though higher blending speeds provide more shear, it can lead to greater dusting resulting in segregation of fines. This means that the fines become air-borne and settle on top of the powder bed once the blender has been stopped. There is also a critical speed which, if approached diminishes blending efficiency considerably. As the revolutions per minute increases, the centrifugal forces at the extreme points of the blender exceeds the gravitation forces required for blending. Consequently, the powder tends to gravitate to the outer walls of the blender shell. As the size of the blender increases, the rotational speed decreases usually in proportion to the peripheral speed of the blender extreme. V-blenders are designed to operate at 50% to 80% of the critical speed. Discharge from the V-blender is normally through the apex port which is fitted with a discharge valve.

Advantages

- Twin shell blenders offers short blending times usually 5 to 15 min and the less space requirements and its efficient homogeneous mixing capability makes it a choice of blender.

- Particle size reduction and attrition are minimized due to the absence of any moving blades. Hence it can be used for fragile materials.

- Charging and discharging of material is easy.

- The shape of blender body such as the sanitary butterfly discharge valve results in a near complete discharge of product.

- The absence of shaft projection eliminates product contamination.

- Provision of the intensifier bars makes this blender adaptable for drying as well as wet mixing, and mixing of fines, coarse particle compositions and cohesive powders.

- There is no dust generation during feeding and discharging of the product.

- It is possible to control of the temperature of the product mix and can have provision of injecting a liquid to aid mixing.

- It is suitable for mixing ingredients as low as 5% of the total blend size.

Disadvantages

(i) They require high headroom space for equipment installation and operation.

(ii) They are not suited for blending particles of different sizes and densities, which may segregate at the time of discharge.

(iii) Provision of intensifier bars may lead to undesired particle attrition and has intensifier bar shaft sealing and cleaning problems.

(iv) The low mixing shear action limits its use for some very soft powders or granules.

Applications of twin shell blender

(i) V-blenders are used for the dry blending of free-flowing solids in the pharmaceutical and nutraceutical industries.

(ii) General applications of V-blenders are in the mixing of food products, milk powder, coffee, dry flavours, ceramics powders, pigments, pesticides and herbicides, plastic powders, animal feeds, spice blends, fertilizers, baby foods, cosmetics, and polyethylene.

(iii) This type of blender is primarily used for mixing up to 10 ingredients.

Double Cone Blender