The planetary mixer is a high-shear mixer and is available with a variable speed drive. It is suitable for mixing ointments, inks, sauces, pastes, and foam used in the pharmaceutical, food, chemical, and allied industries.

Table of Contents

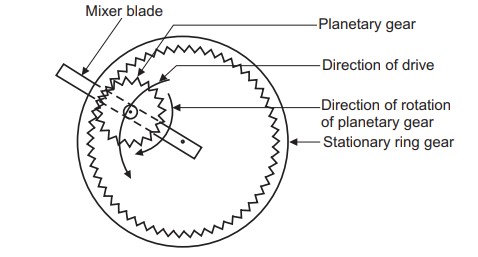

Principle of Planetary Mixer

The principle of planetary mixer is based on the rotation of planetary blades on their own axis while they travel around the center of the mixing bowl which ensures complete and effective mixing. The mixing blades revolve in opposite direction to sweep the entire circumference of the vessel as well as rotate around its own axis. Highest level of mixing is achieved in short intervals.

Construction of Planetary Mixer

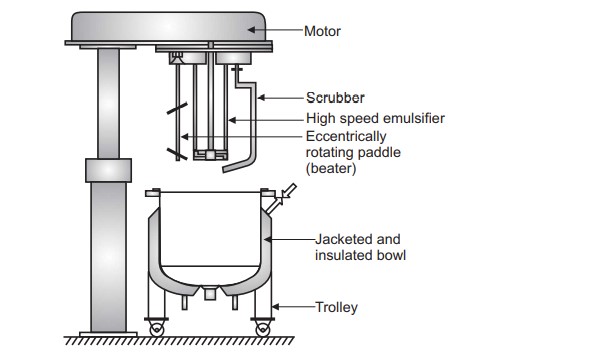

Planetary mixer bowl, all its contact parts, and beater are made up of stainless steel (SS304) or (SS316) materials, as per requirements. The mixer bowl is divided in to an upper cylindrical section and a lower hemispherical section. The mixing elements (beaters) used for mixing are shaped to match the lower curved surface of the bowl. The most commonly used beaters are the batter, wire whip, and hook type. Planetary mixers are provided with a high-speed emulsifiers in the center of the bowl. Scrapers with Teflon edges may be provided to wipe any material which may stick onto the internal surface of the bowl. Single planetary mixers are constructed in a range of sizes.

There are multiple bowls and beater designs with the same mixer assembly. For small-size mixers, the lifting and lowering of the bowl are through a manual arrangement. In the case of larger units bowl is lowered beneath the motor along with the beater using a motorized or hydraulically operated mechanical arrangement. There is a facility for the movement of the bowl away from the machine using a suitable trolley with wheels. The single planetary mixers are available in small sizes to production size units with capacities of 50 – 300 L. The mixer motor may range up to 1.0 HP for smaller sizes to about 10 – 15 HP for the 300 L, depending on the material to be mixed.

Working of Planetary Mixer

The planetary mixer works on homogenous mixing action. The material to be mixed is loaded in to the bowl. The planetary motion of the beater enables faster and better mixing of material in a considerably short time. The operation at slow speed is suitable for dry mixing with less dust generation and faster speed for kneading operation during wet granulation. The bowl is secured to a semi-circular frame at the time of mixing. Beaters can be intermittently cleaned completely by removing from a vessel or by rotating the blades in the vessel loaded with solvent. After the mixing is completed, the bowl is lowered and can be easily detached and removed from the mixer assembly. The mixed contents are discharged either by hand scooping or through a bottom discharge valve or by hydraulically operated automatic discharge systems.

Advantages

(i) There are virtually no dead spaces in the mixing bowl.

(ii) Single planetary mixers are relatively inexpensive and versatile in applications,

(iii) Portable mixing bowl with a top-mounted agitator has a dual advantage of material transfer with no risk of packing contamination.

(iv) The product quality is better and more homogeneous.

(v) The noise and vibration levels are low due to the use of insulating materials and strong

and solid construction.

(vi) Security cover or bars and sensor technology reduces occupational labor accidents.

(vii) It exhibits a higher level of hygienic products and the mixer is easy to clean.

(viii) The sturdy equipment has long durability as it is made up of high-quality stainless steel.

(ix) Being compact equipment, it requires less space.

Disadvantages

(i) The equipment generates heat which may be unsuitable for proper mixing.

(ii) When handling high viscosity materials the energy required is more.

(iii) As this equipment consists of moving parts maintenance is required.

(iv) As labor requirement is more, the process cost is also high.

Applications of Planetary Mixer

(i) The single planetary mixer has common applications in the pharmaceutical, chemical, and cosmetic industries.

(ii) Planetary mixers are used for wet/dry solid-solid materials mixing.

(iii) It is used in the manufacturing of starch paste heated with steam or thermal fluid in an electrically heating jacket with or without a flush bottom valve for discharge.

(iv) It is used for the dry powder to wet phase mixing for wet granulation.

(v) The single planetary mixer is used for the mixing of light pastes, gels, and dough.

(vi) This mixer is commonly used in the food and bakery industry due to its simple construction and operation.

(vii) These mixers are designed for intensive mixing, dispersing, and kneading of adhesives, sealants, light caulks, pastes, coatings, granulations, and similar products of medium to high viscosity.

Ribbon Mixer Blender