A turbine mixer is another type of process agitator. They are used as an alternative to propellers for mixing low viscosity liquids and typically for the effective mixing of medium viscosity liquids. The velocity of mixing using turbine systems is low compared to propellers.

Table of Contents

Principle of turbine mixer

Turbine mixer agitators can create a turbulent movement of the fluids due to the combination of centrifugal and rotational motion. These combined motions cause effective mixing of low to medium viscosity fluids.

Construction of turbine mixer

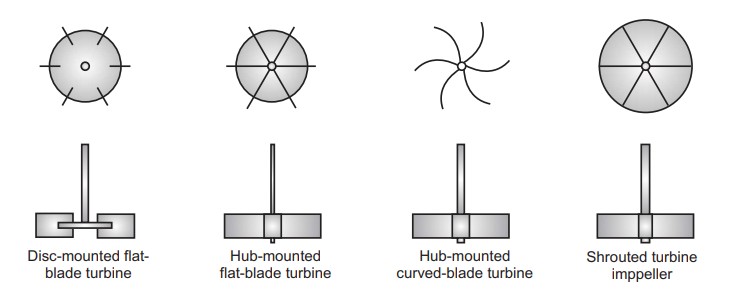

A turbine consists of a circular disc to which a number of short blades are attached. Compared to propellers, the diameter of turbines is approximately 0.13-0.67 to that of the diameter of the vessel, with 0.33:1 being most typical. There is a wide range of turbine designs, shown in the figure below. The blades may be straight, pitched, curved, or disk type. The turbine rotates at a slower speed, usually 50–200 r.p.m. than the propellers. Flat blade turbines produce radial and tangential flow, but as the speed increases, radial flow dominates. A pitched blade turbine produces axial flow. High turbulence and intense shear are observed near the impeller zone of rapid currents. Shear produced by turbines can be further enhanced using a diffuser ring. The diffuser ring is a stationary perforated ring that surrounds the turbine.

Working of turbine mixer

A mixer is filled through with an opening at its top. Usually, it is a pan or drum within which mixing blades revolve about the vertical axis. The variable speed drill with the turbine mixer whips air into the material mixture. The air in the mixture yield bubbles contributing to mixing. The top entry turbine mixer is fitted with various impellers and turbines to suit heat and mass transfer in solids, suspensions, and liquids. This type of mixer does not damage the product. Top entry high shear causes uniform emulsification and homogenization. The mixing blades revolve about the vertical axis.

Advantages

(i) Turbines are used in emulsification as they generate higher shearing forces than propellers even at low pumping rates.

(ii) They are effective in mixing high viscous solutions with a wide range of viscosities up to 7.0 Pa.s.

(iii) They are highly suitable for making dispersion containing 60% solids.

(iv) Turbines are suitable for liquids of large volume and high viscosity with the additional provision of baffles in the tank.

(v) As they generate high radial flow efficiency of mixing is high.

(vi) In low viscous materials of large volumes turbine creates a strong current which spread throughout the tank destroying stagnant pockets.

Disadvantages

(i) They are not preferred for solvents with high viscosity such as more than 20 cP.

(ii) There is the possibility of air entrapment that may cause oxidation of material being mixed.

Applications of turbine mixer

(i) Highly used in chemical reactions and extraction operations. For example, liquid and gas reactions.

(ii) Used in preparing emulsions, suspensions, and syrups.

Double Cone Blender