Table of Contents

Principle of Hammer mill

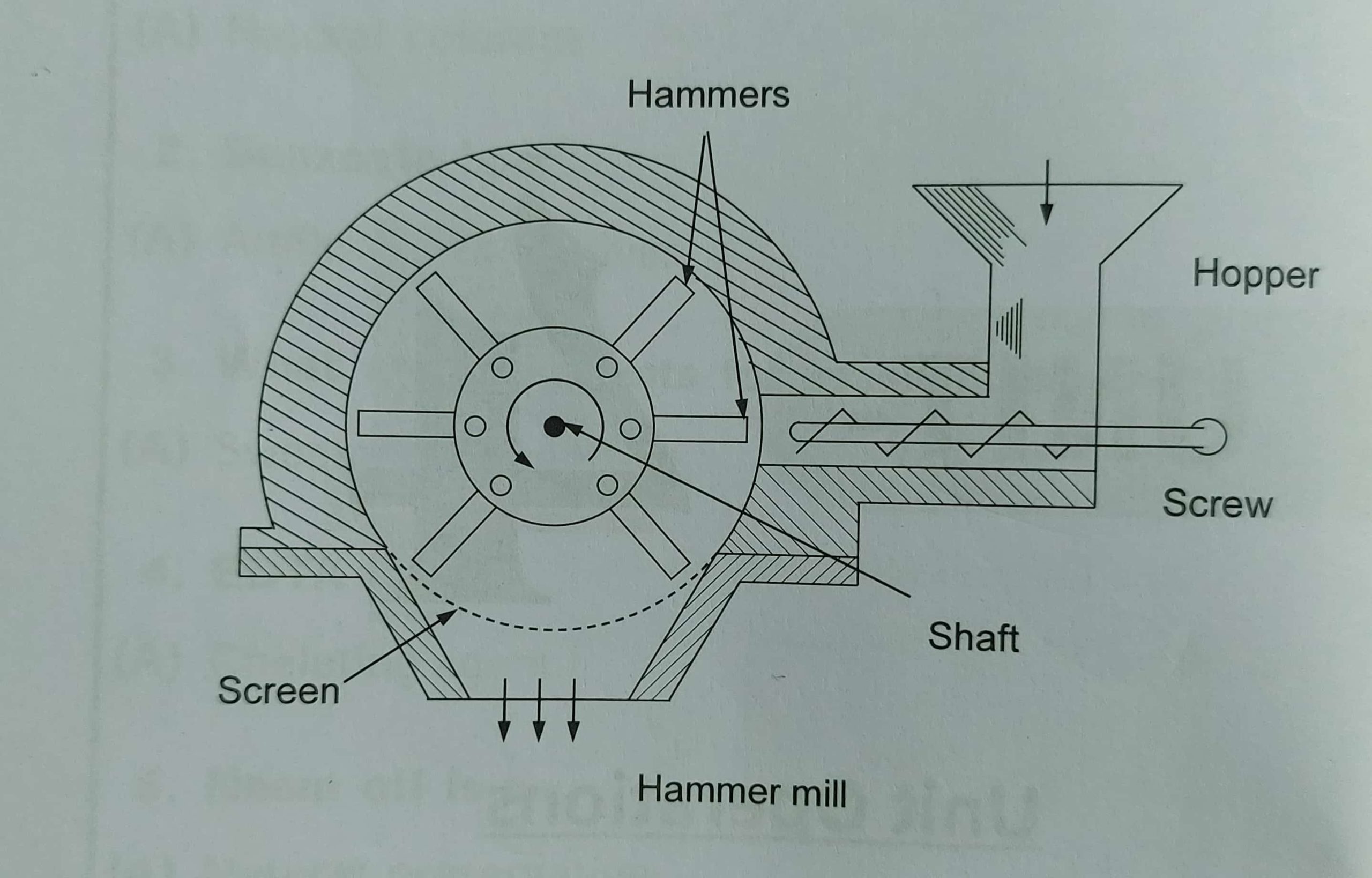

Hammer mill: It works on the principle of impact, i.e. material is more or less stationary and hit by an object moving at high speed.

Construction of Hammer mill

It consists of a stout metal casing, enclosing a central shaft, to which four or more swinging hammers are attached. The lower part of the casing consists of a screen, through which material can pass and collect in a suitable receiver when the desired degree of size reduction is reached.

Working

The material is put into the hopper which is connected to the drum. The material is powdered to the desired size, due to the fast rotation of hammers and is collected under the screen. This mill has the advantage of continuous operation because the chance of jamming is less as the hammers are not fixed. The mill can produce coarse to a moderately fine powder. Due to the high speed of operation, heat is generated which may affect thermolabile drugs or materials.

Uses

The hammer mill is used for producing intermediate grades of powder from almost all types of substances except sticky materials that choke the screen.

What is size reduction?

Size reduction is the process of reducing drugs into smaller pieces, coarse particles, or fine powder.

Size reduction or comminution is the process of reducing drugs (vegetable and chemical substances) into smaller pieces, coarse particles, or fine powder.

The following are the methods of size reduction, in which different mechanisms are involved.

- Cutting

- Compression

- Impact

- Attrition

- Combined impact and attrition.

Also read: What are sweetening agents in pharmaceutical