Table of Contents

Principle of ball mill

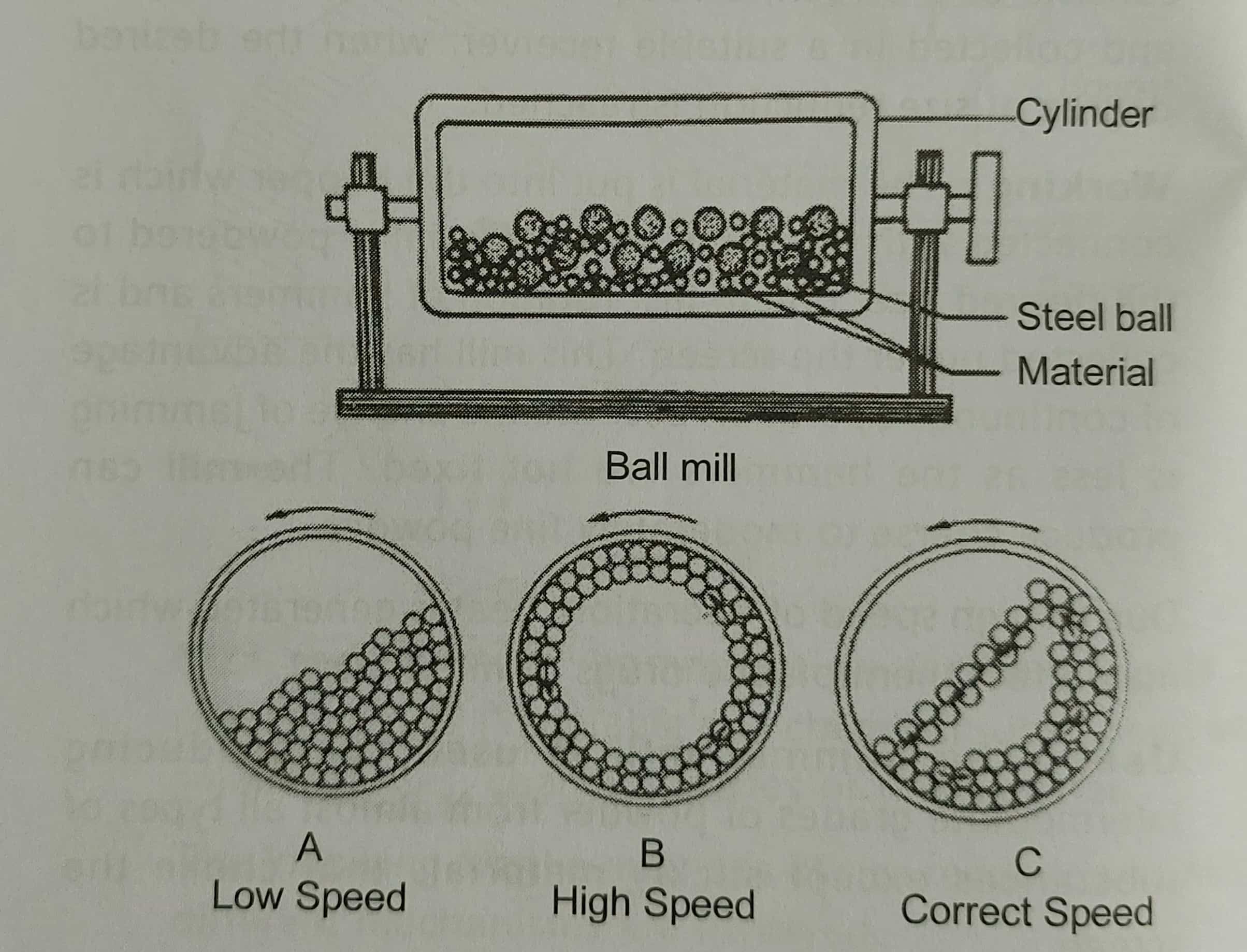

Ball mill: It works on the principle of impact and attrition.

Construction of ball mill

It consists of a hollow cylinder that is mounted on a metallic frame in such a way, that it can be rotated on its longitudinal axis. The cylinder contains balls that occupy 30-50% of the mill volume The weight of the balls is kept constant. The ball size depends on the size of the feed and the diameter of the mill. The cylinder and balls are made of metal and are usually lined with chrome. In the pharmaceutical industry. sometimes the cylinder of the ball mill is lined with rubber or porcelain. The balls used in these mills are also made of rubber or porcelain.

Working of ball mill

The drug to be ground is put into the cylinder of the mill and rotated. The speed of rotation is very important. The speed of rotation is very important. At a low speed, the mass of balls will slide or roll over each other and only a negligible amount of size reduction will occur.

At a high speed, the ball will be thrown out to the walls by centrifugal force and no grinding will occur. But at about 2/3rd of the speed, the centrifugal force just occurs with the result that the ball is carried almost to the top of the mill and then falls in. In this way, the maximum size reduction is affected by the impact of particles between the balls and by attrition between the balls. After a suitable time, the material is taken out and passed through a sieve to get powder of the required size. Uses: The mill is used to grind brittle drugs to a fine powder.

Advantages

- It can produce very fine powders.

- It can be used for continuous operation if a sieve or classifier is attached to the mill.

- It is capable of grinding a large variety of materials of different characters and of different degrees of hardness.

- It is suitable for both wet and dry grinding processes.

- It can be used to grind toxic materials as it can be used in a completely enclosed form.

Disadvantages

- The ball mill is a very noisy machine.

- Wear occurs from the balls as well as from the casing. which may result in contamination of the product.