As we know, an evaporator is a heat exchanger where in liquid is boiled to produce vapour and simultaneously it generates a low-pressure steam. This steam is further used as the heating medium for another following evaporator. Thus the second evaporator is a low-pressure boiler. The utilization of steam in first evaporator is called as first effect. The vapours generated in first evaporators are used for the following the second evaporator as heating source so it is called as the second effect. All individual evaporators are single effect evaporators. To be used them as multiple they need to be connected within series.

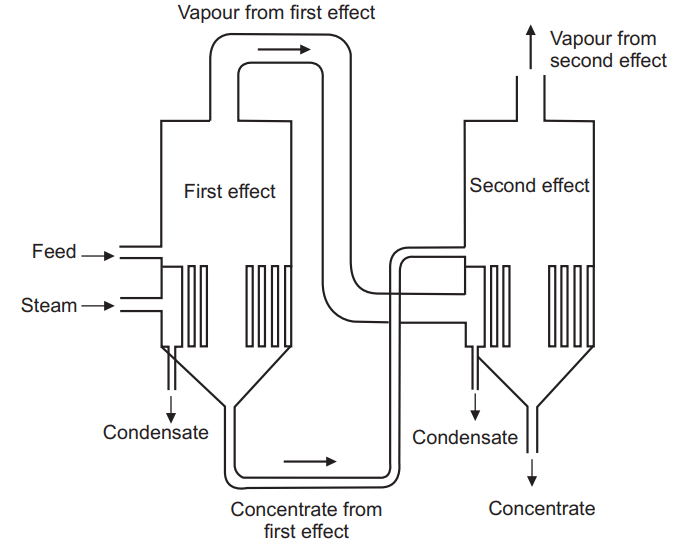

For example, consider two evaporators are connected in such a way that vapors from first evaporator are supplied to the steam chest of the following evaporator as shown in the Figure below, making up a two effect evaporator.

If the liquid is to be evaporated in each effect, and if the boiling point of this liquid is unaffected by the solute concentration, then a heat balance for the first evaporator is written as:

q1 = U1 A1 (Ts – T1)—–5.1

= U1 A1 ∆T1 ——5.2

Where, q1 = Rate of heat transfer

U1 = Overall heat transfer coefficient in evaporator 1

A1 = Heat-transfer area in evaporator 1

Ts= Temperature of condensing steam from the boiler

T1 = The boiling temperature of the liquid in evaporator 1

∆T1 = (Ts− T1 ) = Temperature difference in evaporator 1.

Similarly, in the second evaporator the “steam” is a vapor from the first evaporator and this condensates at approximately the same temperature at which it boiled, since pressure changes are negligible. Thus, using subscript 2 for the conditions in the second evaporator the rate of heat transfer in second effect can be calculated using equation (5.4).

q2 = U2 A2 (T1 – T2) —–5.3

= U2 A2 ∆T —–5.4

If the evaporators are operating in balance that all of the vapors from the first effect are condensing and in their turn evaporates vapors in the second effect. In addition, if it is assumed that heat losses are least, no boiling-point elevation of concentrated solution and the feed input is at its boiling point, then at this condition the heat transfer relation can be expressed as:

q1 = q2 —-5.5

If the evaporators are of the same type and size (i.e. A1 = A2), the above equations can be combined as: U2 /U1 = T1 /T2 —-(5.6)

Table of Contents

Steam feeding in multiple effect evaporators

In case of two effect evaporators, the temperature in the steam chest of first evaporator is higher than in the second evaporator. The vapours generated in the first evaporator will the effect boiling of liquid in second evaporator; the boiling temperature in the second evaporator must be lower so that effect must be under lower pressure. The pressure in the second effect must be reduced below that in the first effect.

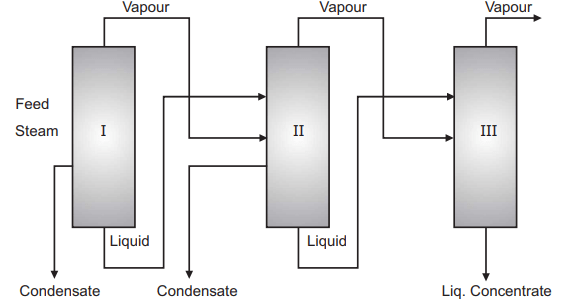

Forward feed multiple effect evaporators

In some cases, the first effect may be at a pressure above atmospheric; or the first effect may be at atmospheric pressure and the second and subsequent effects have therefore to be under further lower pressures. Under lower pressures, the liquid feed progress is simplest if it passes from first effect to second effect, to third effect, and so on. In these situations the feed flows without pumping. This is called forward feed, showing in the Figure below. The most concentrated liquid products occur in the last effect of the process.

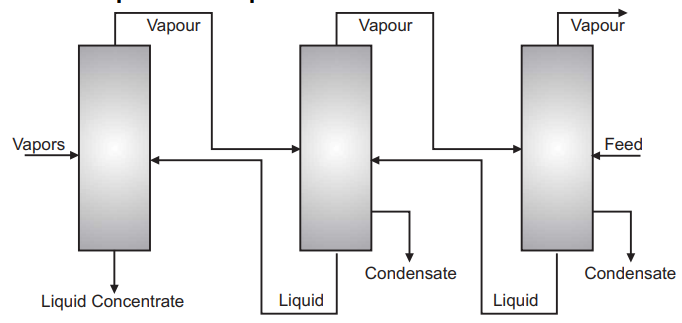

Backward feed multiple effect evaporators

In backward feed evaporator the feed may pass the last effect and proceeds to the first. This is in reverse of forward feed multiple effect evaporators. In backward feed the liquid is pumped from one effect to the next against the pressure drops, showing in the above Figure. The concentrated viscous liquids are at the highest temperatures in the first effect and thus have larger evaporation capacity than forward feed systems.

Parallel feed

In this method a hot saturated solution of the feed is directly fed to each of the three effects in parallel without transferring the materials from the one effect to the other. The parallel feed arrangement is commonly used in the concentration of the salts solution where the solute crystallizes on concentration without increasing the viscosity.

Construction of multiple Effect Evaporators

A multiple effect evaporator system for concentrating a process liquid consists of more than one evaporator effects arranged in series, each effect includes a process liquid inlet and a process liquid outlet; a heating fluid inlet and heating fluid outlet and an evaporative condenser provided with liquid inlet. Two effect evaporators are connected together with the piping arrangement so that the vapors from the calandria of the first effect are used to heat the calandria of the second effect. The calandria of the second effect is used as a condenser for the first effect. The latent heat of vaporization is used to evaporate more quantity of the liquid. The vapour from the second effect then taken to a condenser and converted in to the liquids. In general not more than two or three effects are combined together to have economical and efficient evaporation of liquids. The construction of the multiple effect evaporators uses three evaporators so it is called as triple effect evaporators. The vapour from the first evaporator serves as heating medium for the second evaporator. Similarly, vapour from the second evaporator serves as a heating medium for the third evaporator. Last evaporator is connected to a vacuum pump.

Working of multiple Effect Evaporators

Multiple effect evaporators (3 – stages) is a long tube forced circulation type evaporators where in the first effect high pressure steam is used to evaporate solvent from the feed. The evaporated solvent in the form of vapor is used for evaporating the feed in the second effect at atmospheric pressure. Evaporated solvent from the second stage is used for evaporating concentrating feed in the third effect under vacuum. Finally evaporated solvent from the third effect is condensed in the steam condenser using cooling water on other side. Condensate from all the three effects is collected in condensate receiving tanks, which is pure solvent and hence reused in the process.

Advantages of multiple Effect Evaporator

(i) It is suitable for large scale and continuous operation.

(ii) It is highly economical when compared with single effect.

(iii) About five evaporators can be attached in series.

(iv) Minimizes the energy input required to evaporate undesirable solvent.

Applications of multiple Effect Evaporators

(i) Used in the manufacture of the cascara extract.

(ii) Used in the manufacture of salts and caustic soda.

(iii) Used in the manufacture of salts.

(iv) Used in order to recover expensive solvents such as hexane which would otherwise be wasted.

(v) Recovery of sodium hydroxide in Kraft pulping.

(vi) Cutting down waste handling cost is another major application

(vii) To get a concentrated product and to improve the stability of the products.

(viii) Used in the concentration of the sodium salts that is obtained as a by-product from the production of p-cresol.

(ix) In the food and drink industry, for example, coffee, need to go through an evaporation step during processing.

Make sure Check our Article: Horizontal Tube Evaporator