Forced circulation evaporator uses force to drive the liquid through the evaporator tubes, thus produces high tube velocities. A high-efficiency circulating pump, designed for large volume and sufficient head, is used to supply the force. Proper design results in controlled temperature rise, controlled temperature difference, and tube velocities that give optimum heat transfer. A forced circulation evaporator conducts evaporation under reduced pressure, which is used to evaporate thermolabile substances.

Table of Contents

Principle of forced Circulation Evaporator

In forced circulation evaporator liquid is circulated through the tubes at high pressure by means of a pump. Hence boiling does not take places because the boiling point is elevated. Forced circulation of the liquids also creates some form of agitation. When the liquid leaves the tubes and enters the vapor head, the pressure falls suddenly. This leads to the flashing of super heated liquor leading to evaporation of feed.

Construction of forced Circulation Evaporator

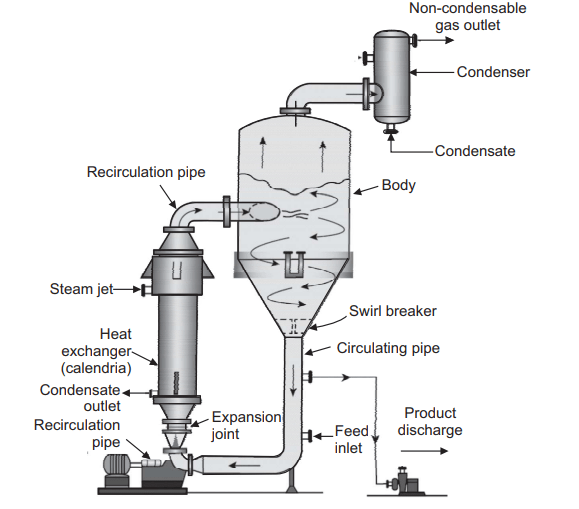

In these types of evaporators, pumps are fitted to circulate the heating of the contents in it. The forced circulation evaporator consists of steam jacketed tubes held between two tube sheets, shown in Figure. The tube measures 0.1 m inside diameter and 2.5 m long. The parts of the tubes project into the vapor head which consists of a deflector. The vapor head is connected to a return pipe which runs downwards and enters in to the inlet of a pump. The liquid is circulated by means of a pump. As it is under pressure in the tubes the boiling point is raised (but no boling take places) and it enters into the body of the evaporator.

Working of forced Circulation Evaporator

Steam is introduced in to the calendria. The pump sends the liquid to the tube with a positive velocity. As the liquid move up through the tube it gets heated and begins to boil. As result, the vapor and liquid mixture rushes out of the tubes at a high velocity. This mixture strikes the deflector in a manner that effective separation of liquid and vapor takes place. The vapour enters the cyclone separator and leaves the equipment. The concentrated liquid is circulated through the pump for further evaporation. Finally, the concentrated product is collected at the bottom from the discharge outlet.

Advantages of forced Circulation Evaporator

(i) There is a rapid movement of liquid due to the high heat transfer coefficient.

(ii) The liquid entering the circulation evaporator boils in the separator and not on a heating surface hence minimizing fouling.

(iii) Salting, scaling, and fouling are not possible due to forced circulation.

(iv) These evaporators are suitable for thermolabile substances because of rapid evaporation.

(v) It is suitable for viscous preparation because a pumping mechanism is used.

(vi) These evaporators are also used for liquids with high solids content.

(vii) Circulation evaporators are fairly compact and are easy to clean and operate.

Disadvantages

(i) The hold-up time of liquids is high.

(ii) The equipment is expensive as well as the power requirement is high.

(iii) It has high maintenance costs.

(iv) The increased velocity can cause the equipment to corrode at a faster rate, which increases the overall maintenance cost.

Applications

(i) Forced circulation evaporator is used to concentrate thermolabile substance solutions.

(ii) It is used for the concentration of insulin and liver extracts.

(iii) It is well suited for crystallizing operations where crystals are to be suspended at all times.

(iv) These evaporators are used in the production of salt, corn steep water, and calcium carbonate.

(v) It is used for effluent treatment in pharmaceutical industries.

(vi) Forced circulation chambers can be superimposed on each other to form a multi-effect tower which can be utilized for the increasing concentration of refined sugar and syrups.

Make sure check our Amazing article: Horizontal Tube Evaporator