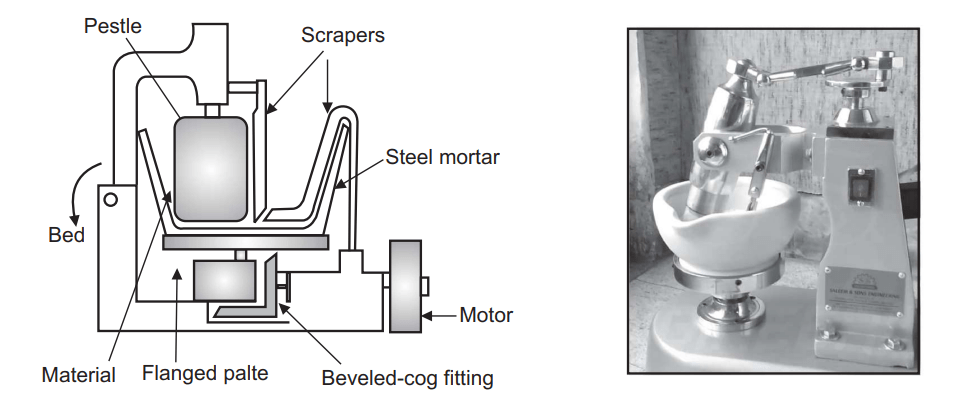

End Runner Mill

An automated version of mortar and pestle size reduction equipment, the end-runner mill is comparable to the edge runner mill. The friction of material between the mortar and the pestle causes a heavy-weight pestle to revolve when the mortar is rotated by a motor at the base. Principle of end runner mill The principle of … Read more