A pulverizer, micronizer, and jet mill is also known as a fluid energy mill. It’s utilized for fine grinding and controlling particle size. The particles are reduced using an attrition and impact mechanism involving air or inert gas injected through the nozzles in the chamber. This mill is primarily used to finely grind heat-sensitive materials.

Table of Contents

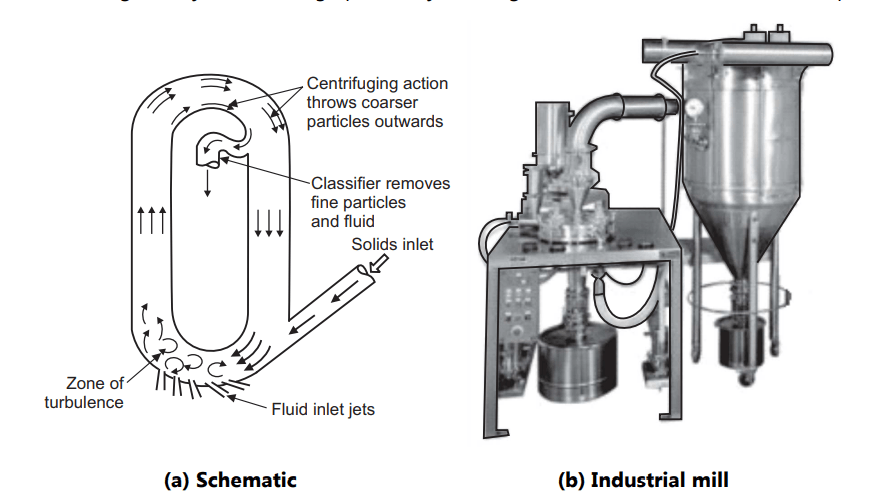

Principle of fluid energy mill

It is based on the effect and attrition idea. The inlet and exits are connected by a classifier, which stops particles from passing until they are fine enough, as shown in Fig. 2.5. (a). It aids in the size and shapes determination of particles. The efficiency of air/inert gas is directly proportional to its speed. When solids are added into the stream through the inlet, there is a lot of turbulence, collision, and attritional forces between the particles. Particles break down as a result of the irregular motion between the feed and the air. Because this mill does not generate heat, it is ideal for grinding heat-sensitive materials.

Construction of Fluid Energy Mill

The main basic parts present in the fluidized energy mill are inlet, nozzles, classifier, and hollow toroid (Loop). Through the inlet, the solid material is introduced into the chamber made of stainless steel. The air or the inert gas is introduced through nozzles into the chamber at the bottom of the loop. The cyclone separator called classifier is attached at the top from which the fine particles are collected. The loop of a pipe has a diameter of 20 to 200 mm depending on the overall height of the loop which may be up to about 2 meters. The high pressure of fluid exerts a high-velocity circulation in the loop in a very turbulent manner. A classifier is incorporated into the system so that particles are retained in a loop until sufficiently fine.

Fluidized energy mills are available in other subclasses. They have no moving parts and are primarily distinguished from one another by the configuration and/or shape of their chambers, nozzles, and classifiers. They include tangential jet, loop/oval, opposed jet, opposed jet with dynamic classifiers, fluidized bed, moving target, fixed target, and high

pressure homogenizers.

Working of Fluid Energy Mill

The feed introduced into the fluid energy mill is pre-treated to reduce the particles size to the order of 100 meshes. This enables the process to yield a product as small as 5 micrometers or less. Despite this, mills capable of output up to 40 kg/h are also available. Air or inert gas is injected as a high-pressure jet through nozzles at the bottom of the loop.

The powder particles in the mill are accelerated to high velocity by gas pressure. The kinetic energy of the air and the resulting turbulence due to high pressure causes inter-particle collision and attrition due to particle-wall contact resulting in particle size reduction up to 5 µm. Size reduction in this mill also depends on the energy supplied by compressed air that enters the grinding chamber at high speed. The fluidized effect carries particles to a classifier zone where the larger particles are retained until they become sufficiently fine. Fine particles are collected through a classifier.

Types of fluid energy mills

There are two main classes of pulverizers (fluid energy mills)

(i) Air Swept Pulverizer: In this mill, the particles along with air are fed into the mill inlet. Air swept pulverizers use air to transport particles to the pulverizing section of the apparatus. The beater plates support the hammers and distribute the particles around the periphery of the grinding chamber. The hammers grind the solid against the liner of the

grinding chamber. The beater plates rotate between 1600 and 7000 rpm to reduce the size of the incoming particles. The classifier plate separates the fine product and exits through the discharge outlet. The larger material is back feed to the mill inlet through the recycle housing.

(ii) Air Impact Pulverizer: In air impact pulverizers superheated steam or compressed air produces the force that reduces the size of large particles. It results in the smashing of the particles into smaller particles. This pulverizer uses high-speed air to pulverize the particles. The products from both air swept and air impact pulverizers produce particles that do not require further sieving or classifying.

Factors determining efficiency of fluid energy mills

(i) The speed of air/inert gas.

(ii) Feed rate and size.

(iii) The configuration of the mill.

(iv) Design of the classifier.

(v) The position of the nozzle.

(vi) The impact between the feed and air.

Uses of fluid energy mill

- Fluid energy mill is used when fine powders are required, for example, antibiotics, sulphonamides and vitamins.

- Suitable for laboratories where small samples are needed.

- The mill is used to grind heat sensitive material to fine powder.

- The major advantage is fine grinding of pigments, kaolin, zircon, titanium and calcium, alumina, ceramic frit, powder insecticides such as DDT, diatomaceous earth, feldspar, fluorspar, graphite, gypsum, iron ore, iron oxide, iron powder, limestone, polymers, rare earth ores carbon, talc etc.

- It is the choice of mill when higher degree of drug purity is required

Merits:

- The particle size of the product is smaller than produced by any other method.

- Expansion of gases at the nozzles leads to cooling, counteracting the frictional heat thus protecting heat-sensitive materials.

- There is little or no abrasion of the mill and so no contamination of the product.

- To protect sensitive drugs from oxidative degradation this mill has facility to use inert gases.

- Presence of classifier permits control of particle size and particle size distribution.

- Suitable for size reduction of materials capable of generating a static charge.

- The process is suitable for friable, abrasive or crystalline materials.

- Air needed is freely available.

- Homogeneous blend of large range of sizes available.

- The equipment is easily sterilized.

- At the end of milling product particle size between 2 and 10 µm is obtained.

Demerits:

- This mill is energy consuming and the energy consumed per ton of milled product is high.

- High headspace is required.

- Coarse feed size is not suitable.

- The feeding device may be clogged with the clumped materials.

- Special feeding devices should be provided for the feeding of the materials.

- The use of compressed air leads to the generation of static electricity.

- Material recovered in the collection bags is difficult or impossible to remove by the normal blow back procedures.

- Tendency to form aggregates or agglomerates after milling.

- generation of amorphous content due to high energy impact.

- Formation of unwanted ultra-fine particles.

Make sure read also our Amazing article: hammer mill