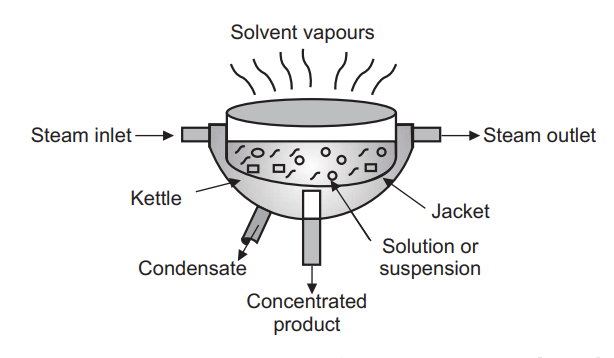

The evaporating pan is also called a steam jacketed kettle. In this type of evaporator, the movement of the liquid to be evaporated is due to the convection currents set-up by the heating process. It is a type of natural circulation evaporator. It consists of a hemispherical pan surrounded by a steam jacket. The hemispherical shape provides a large surface area for the evaporation to takes place. The evaporation pan may be fixed and the contents are discharged from the outlet provided at the bottom of pan. In some cases, the evaporators are mounted in such a way that they can be tilted on either side to remove the concentrated product. The evaporating pans are heated by the steam which enters the jacket through inlet and leaves it from the outlet. The heat from the steam in a jacket is utilized for evaporating liquid in pan.

Table of Contents

Principle of Steam Jacketed Kettle

The mechanisms involved in this evaporation process is conduction and convection so that the heat is transferred by this mechanism to the extract. Evaporating pan containing aqueous extract is provided with ststeam,hich gives out heat to a jacketed kettle. The temperature raises and the escaping tendency of the solvent molecules in to the vapour increases and enhances the vaporization of the solvent molecules.

Construction of Steam Jacketed Kettle

Steam evaporating pan consists of a hemispherical structure with an inner pan called a kettle which is enveloped with an outer pan called a jacket, shown in the Figure below. These two pans are joined to enclose a space through which steam is passed. Several metals have been used for the construction of the kettle. Copper is an excellent material for the kettle due to its superior conductivity. If acidic preparation evaporated in the copper kettle, some of the copper gets dissolved in preparation. In order to avoid this, for acidic preparation is tinned copper kettle is used. Iron is also used for the construction of the jacket because it has low conductivity. Rusting of iron with use is a major problem and to prevent this iron jacket is tinned or enameled on the inner surface. An inlet for the steam and non-condensed gases is provided near the top of the jacket. Condensate leaves the jacket through the outlet provided at the bottom. The kettle is provided with the outlet for the product discharge at its bottom.

Working of Steam Jacketed Kettle

The solution to be evaporated is placed in the kettle, and steam is fed through the inlet and condensate exits through the outlet, providing heat to the content. Manual stirring is required for lesser volumes, and mechanical stirring is required for greater volumes. In the beginning, the rate of evaporation is rapid. To avoid the production of fog from condensed vapour, the chamber where evaporation takes place must have adequate ventilation to evacuate the vapour. Fans are installed to prevent condensation in the room and to speed up the rate of evaporation. The kettle can either be fixed or tilted. A kettle with a capacity of up to 90 litres can be tilted. The concentrated goods are collected at the bottom outlet.

Applications

(i) Evaporating pan is suitable for concentrating aqueous liquids.

(ii) It is suitable for concentrating thermostable liquors, for example, liquorices extracts.

Advantages

(i) Evaporating pan is constructed both for small scale and large scale batch operations.

(ii) It is simple in construction and easy to operate, clean and maintains.

(iii) Its cost of installation and maintenance is low.

(iv) Wide variety of materials such as copper, stainless steel and aluminium etc can be used for the construction of evaporating pan.

(v) Stirring the contents in the pan and removal of the products is easy.

Disadvantages

(i) Natural circulation of the product makes poor heat transfer.

(ii) Deposition of solid may cause decomposition of the product.

(iii) Heating surface is limited and decreases proportionally to increase in the size of the pan.

(iv) It is not suitable for the concentration of thermolabile materials.

(v) It has no provision to operate under reduced pressure.

(vi) No provision to recollect the costly organic solvents.

(vii) Being the evaporating pan open vapours directly pass into the atmosphere. This may cause discomfort to the worker.

(viii) Saturation of the surrounding environment with vapours may slow down the process.

Read this article too: Differences between evaporation and other heat process