The Meta filter is the most commonly used filter in the pharmaceutical industry.

Table of Contents

Principle for meta filter

A meta filter is a type of pressure filter. Pressure filters feed the product to the filter at a pressure greater than that which would arise from gravity alone. The Meta filter functions as a strainer (service filtration) for the separation of particles. The metal rings contain semi-circular projections, which are arranged as a nest to form channels on the edges. This channel offers resistance (strainer) to the flow of solids (forced particles). The clear liquid is collected into a receiver from the top.

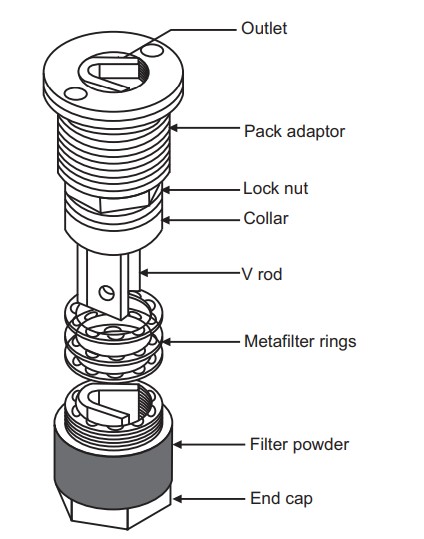

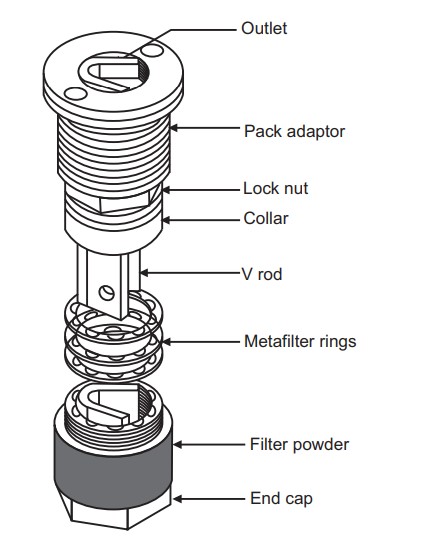

Meta filter construction

The MetaFilter, in its simplest form, consists of a grooved drainage rod on which is packed a series of metal rings. These rings are usually made of stainless steel and are about 15 mm, inside diameter of 22 mm, outer diameter and 0.8 mm in thickness. These rings have a number of semicircular projections on one surface, and when they are packed on the rod, the opening between the rings is about 0.2 mm. The figure is shown below. The height of the projections and the shape of the section of the ring is such that when the rings are packed together, all the same way up, and tightened on the drainage rod with a nut, channels have formed that taper from about 250 µm down to 25 µm. One or more of these packs is mounted in a vessel, and the filter may be operated by pumping in the slurry under pressure or, occasionally, by the application of reduced pressure to the outlet side.

In this form, the Metafilter can be used as a strainer for coarse particles, but for finer particles, a bed of a suitable material such as kieselguhr must be first built up. The pack of rings, therefore, serves essentially as a base on which the true filter medium is supported.

Working for meta filter

Meta filters are placed in a vessel and may be operated by pumping the slurry under pressure or occasionally by the application of reduced pressure to the outlet side. The slurry passes through the channels formed on the edges between the rings. The clear liquid rises-up and collected from the outlet into the receiver. When the vacuum is applied, liquid flows from outside to inside. In this form, a MetaFilter can only be used as a strainer for coarse particles. But for the separation of finer particles, a bed of suitable materials such as Kieselguhr is used. In this way, the pack of rings acts as a base on which the true filter medium is supported.

Advantages

(i) The metafilter is sturdy, having enough strength to handle high pressures with no danger of bursting the filter medium.

(ii) As it has no filter medium as such, the running costs are low and are very economical.

(iii) This filter provides excellent resistance to corrosion and avoids contamination of the most sensitive product.

(iv) It is sustainable to filter off very fine particles.

(v) It can be used to sterilize some liquids by filtration.

(vi) It can also be used to remove larger particles simply by building up a bed of coarse substances, or even by using the Meta filter candle itself if the particles are sufficiently large.

(vii) Removal of the cake is effectively carried out by backflushing with water.

Applications

(i) The small surface of the Metafilter restricts the amount of solids that can be collected. This, together with the ability to separate very fine particles, means that the Metafilter is used almost exclusively for clarification purposes.

(ii) The strength of the Metafilter permits the use of high pressures (15 bars), making it suitable for viscous liquids.

(iii) It can be constructed with the appropriate corrosion-resistant materials.

(iv) Specific examples of pharmaceutical uses include the clarification of syrups, elixirs, injection solutions, and products such as insulin liquors.

Plate and Frame Filter Press