The liquid-to-liquid heat interchanger is single-pass equipment wherein the fluid to be heated is passed only once through the tubes before it gets discharged. Thus, the heat transfer in this case is not efficient. The basic construction includes a few modifications, and its functioning remains approximately the same.

Table of Contents

Working

Baffles are placed outside the tubes. The presence of baffles increases the velocity of liquid outside the tubes. Baffles make the liquid flow more or less right angles to the tubes, which creates more turbulence. This helps in reducing the resistance to heat transfer outside the tubes. The construction of a liquid-to-liquid heat interchanger illustrates the principle of introducing the baffles into the equipment.

Construction of Liquid to Liquid Interchanger

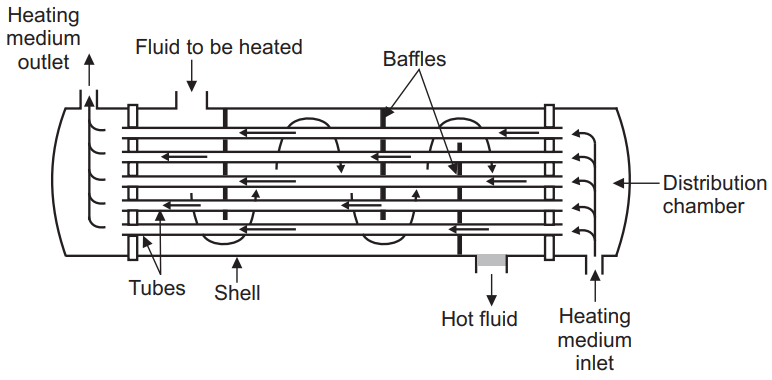

The construction of a liquid-to-liquid heat interchanger is shown in the Figure below. It consists of baffles, tube sheets, spacer rods and the tubes. The most important parts in any heat interchanger are the baffles. An appropriate size of tube sheets is used for the fabrication. Guide rods are fixed to the tube sheets and tighten by means of screws. As mentioned before baffles are placed at right places with the support of guide rods. The baffles are separated with proper spacing using short sections of the same tubing. Tubes are inserted through the perforations in baffles whereas ends of tubes are expanded into the tube sheets. This whole assembly is enclosed in a shell for introducing the heating fluid. The outlet for the heating fluid is at top of one end of interchanger. On both the sides of the tubes, distribution chambers are provided. At the top of left-side chamber, an inlet for fluid to be heated is provided. The outlet for the heated fluid is provided near to the right-side distribution chamber.

Working of Liquid to Liquid Interchanger

The heated fluid (heating medium) is blasted out of the shell’s left-hand top. Outside the tubes, the fluid flows straight down to the bottom. Then it reverses course and rises once more. This technique is repeated until the heater is removed. The velocity of the liquid outside the tubes is increased by baffles. Baffles also allow the fluid to flow at an angle to the tube, resulting in additional turbulence. This aids in the reduction of heat transfer resistance outside of the tubes. The cold fluid’s course is lengthened and the cross-section of the path is reduced by baffles. The baffles heat up, resulting in a larger surface area for heat transfer. During the flow, the tubes are heated at the same time. The film coefficient inside the tube increases as a result. The hot liquid is pumped through the inlet on the distribution chamber’s left side. The liquid passes through the tubes and gets heated. The flow of liquid is single-pass. The heated liquid is collected from the right-hand side distribution chamber.

Advantages

In a liquid-to-liquid interchanger, heat transfer is rapid as the liquid.

(i) passes at high velocity outside the tubes and,

(ii) flows more or less at right angles to the tubes.