Double pipe heat interchangers are efficient equipment for heat transfer as they have a few pipes (tubes) per pass.

Table of Contents

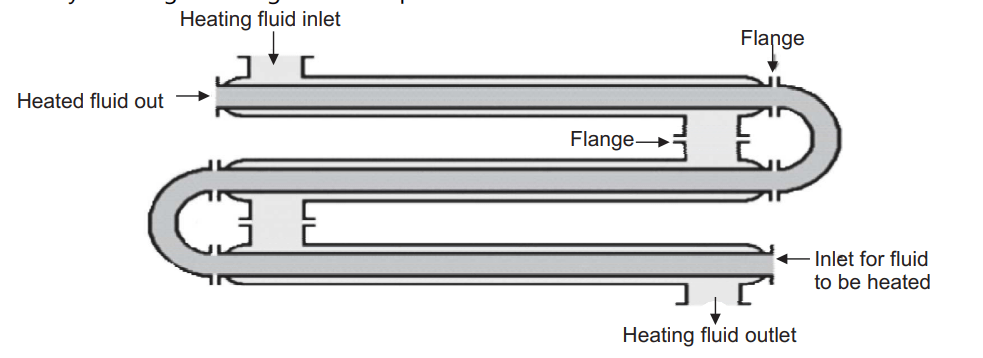

Construction of Double Pipe Heat Interchangers

The double-pipe heat interchanger uses two pipes arranged as one inserted into the other, Figure given below. The inner pipe is used for the pumping of cold fluid to be heated whereas the outer acts as a jacket for the circulation of the hot fluid. The components of this interchanger are inter-connected within the shell. As mentioned earlier the number of pipe sections is limited and in addition, the length of the pipe is also less. The glass tube, standard iron pipe, and graphite materials are used for construction. The metal pipes are assembled with return bends. Few pipes are connected in parallel and stacked vertically and may have longitudinal fins on their outer surface. Outer pipe size varies from 2 to 14 inch with inner tubes varying from 0.75 to 2 inches in size. Some have longitudinal fins on the outside of the inner tube. Counter-current flow in these interchangers is advantageous when very close temperature approaches are required.

Working of Double Pipe Heat Interchangers

The heating medium (hot liquid) is pumped into the outer jacket and is circulated through the annular spaces between them and carried from one part to the next part and finally, it leaves the jacket at the bottom on the right side. During the movement of fluid, the pipes get heated and thus hot fluid loses its temperature. The fluid to be heated is pumped into the inner tube through the inlet provided on the right side. The liquid gets heated up and flows through the bent tubes into the part of the pipe. The liquid further gets heated during flow and finally discharges through the exits point on the left side.

Uses

(i) Double pipe heat interchanger is useful when not more than 0.9 to 1.4 m2 of the surface is required.

(ii) It is best suited when the volume of liquid inside tubes is less and obtains desired velocity and the size of the tube.

(iii) Since, one liquid flows through the inside of the pipe and the second liquid flows through the annular space between the pipes, these are primarily used for low flow rates, high-temperature drops, and high-pressure applications.