Table of Contents

Theory Fluid bed dryer

Fluid bed dryer: If gas is allowed to flow upward through a bed of solid particles at a velocity greater than the setting velocity of the particles, the particles are partially suspended in the gas stream. The resultant mixture of solids and gas behaves like a liquid and the solids are said to be fluidized. Each individual solid particle is surrounded by the drying gas with the result that drying takes place in a much shorter period.

Two types of fluidized bed dryers are used

- Vertical fluidized bed dryers.

- Horizontal fluidized bed dryers.

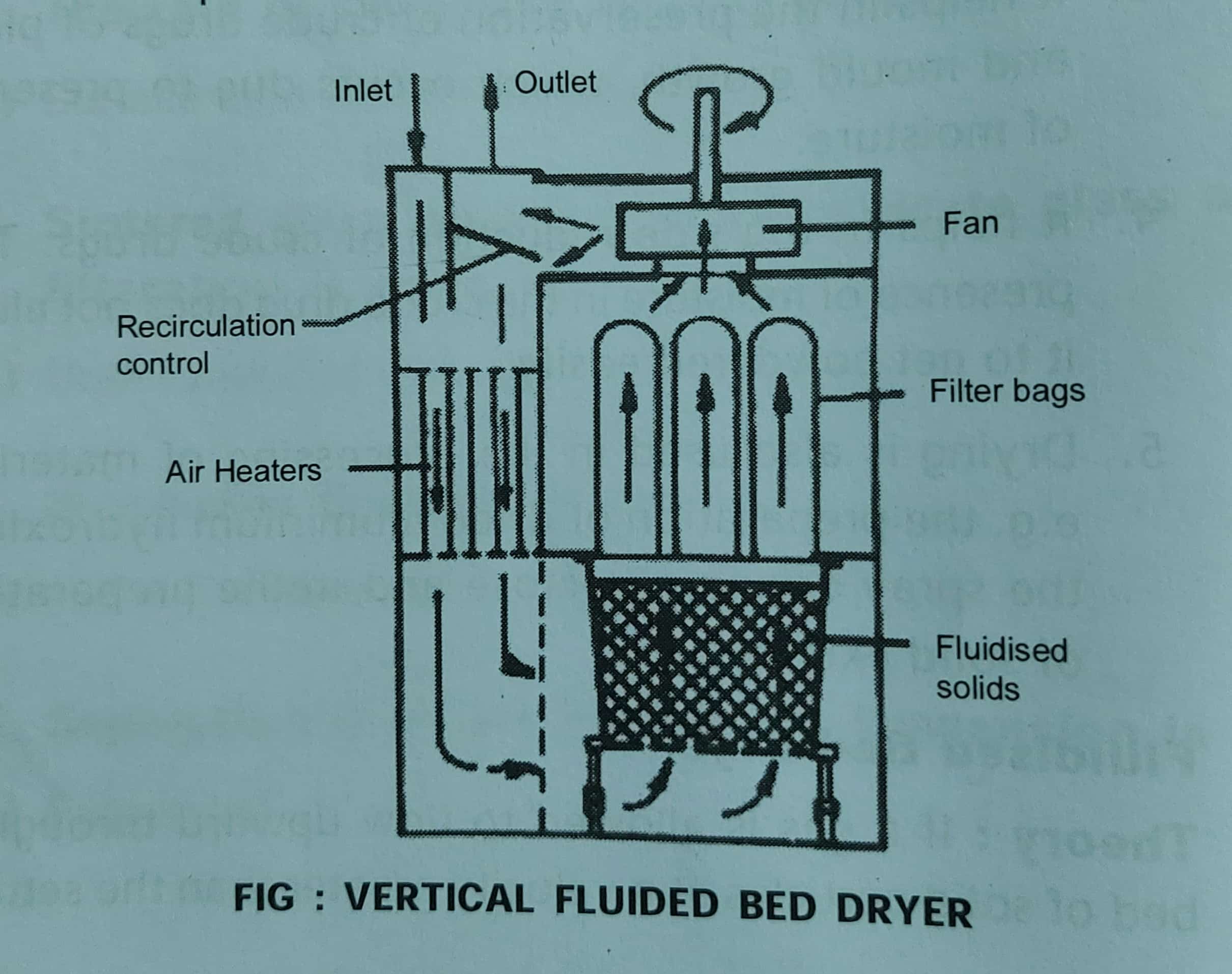

A typical vertical fluidized bed dryer is shown in fig. The fluidizing air stream is induced by a fan which is mounted in the upper part of the dryer. The air is heated to the required temperature in air heaters and passed through the wet material contained in a drying chamber fitted with a wire mesh support at the bottom. The airflow rate is adjusted by means of re-circulation control and fabric filter bags are provided to prevent the passage of fine particles. Horizontal vibrating conveyer fluidized bed dryers are used for the continuous drying of a large volume of material.

Advantages of Fluid bed dryer

- It gives a high drying rate. The fluidized bed dryer method is 15 times faster than the routine method of a tray dryer.

- The method is suitable for drying thermolabile materials because heating time is minimized.

- In a fluidized bed dryer, drying takes place from individual particles and not from the entire bed. As such most of the drying takes place at a constant rate and there is less danger of overheating.

- The temperature inside the fluidized bed dryer can be controlled moreover the temperature is uniform.

- The free movement of individual particles prevents the risk of soluble materials migrating which may occur in static beds.

- The fluidized bed dryer has a high output and occupies a small floor space.

- It can be used for drying any powdered material but it is mostly used for drying of granules meant for the manufacture of tablets.

Disadvantages of Fluid bed dryer

- The turbulence produced when hot air is passed through the material may cause attrition of some material, which leads to the production of fines.

- The vigorous movement of solid particles in hot air can lead to the generation of an electric charge. Hence suitable precautions must be taken in this regard.

Applications of Drying

- In the pharmaceutical industry, it is used as a unit process in the manufacture of granules which can be dispensed in bulk or converted into tablets or capsules.

- Drying can also be used to reduce the bulk and weight of the material, thereby lowering the cost of transportation and storage.

- It helps in the preservation of crude drugs of plant and mould growth, which occurs due to the presence of moisture.

- It helps in the side reduction of crude drugs. The presence of moisture in the crude drug does not allow it to get powdered easily.

- Drying is also used in the processing of materials e.g. the preparation of dried aluminum hydroxide, the spray drying of lactose, and the preparation of solid extracts.