A heat exchanger is a device that transfers heat from one fluid (a liquid or gas) to another fluid (another liquid or gas), with the two fluids being at different temperatures and in thermal contact. There are usually no external heat and work interactions in heat exchangers. Transfer processes, number of fluids, degree of surface compactness, construction features, flow patterns, and heat transfer mechanisms are all used to classify heat exchangers.

Table of Contents

Applications of heat exchangers

(i) Heating or cooling of a fluid stream.

(ii) Evaporation or condensation of single- or multi-component fluid streams.

(iii) To recover or reject heat.

(iv) Sterilize, pasteurize, fractionate, distill, concentrate, crystallize, or control process fluids.

(v) Chemical and petrochemical plants.

(vi) Air conditioning systems.

(vii) Power production.

(viii) Waste heat recovery.

(ix) Automobile radiator.

(x) Central heating system.

(xi) Electronic parts.

Classification of heat exchangers

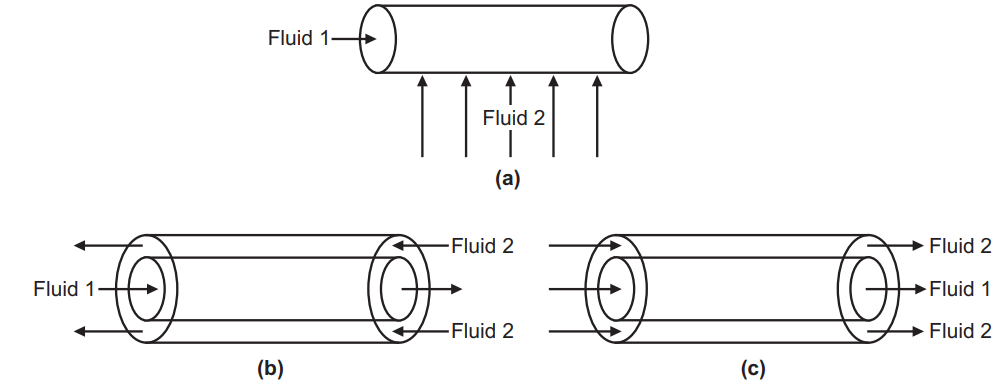

In general, based on the relative flow direction of the two fluid streams heat exchanger are classified into two general classes as follows.

(i) Crossflow exchangers:

Both the fluid streams cross each other in space at a right angle, Fig. 4.4(a).

(ii) Parallel flow exchangers:

Both the fluid streams move in parallel directions in space. For example, shell and tube heat exchanger. If the fluid flows in the parallel direction, two situations may arise.

(a) Fluids flow in the same direction.

(b) Fluids flow in opposite directions.

When the fluid flow is in the same direction it is called “Parallel-flow” heat exchangers and

when it is in the opposite direction called “Co-current flow” heat exchangers, Fig. 4.4.

Make sure check our amazing article on: What is heat transfer?