Table of Contents

Filter aid

Filter Aids are a group of inert materials that can be used in filtration pretreatment. Usually, the resistance to flow due to the filter medium itself is very low but will increase as a layer of solids builds up, blocking the pores of the medium and forming a solid cake. The filter aid is used to prevent the medium from becoming blocked and to form an open, porous cake, reducing the resistance to the flow of the filtrate.

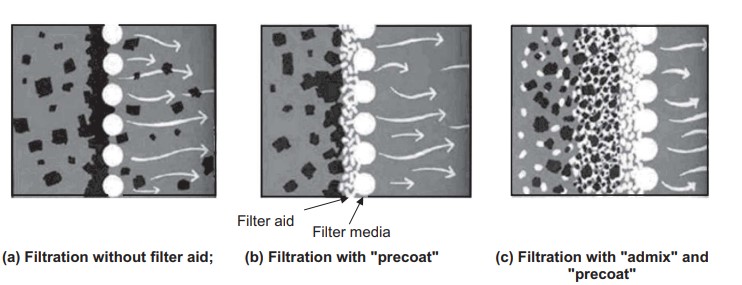

There are two objectives related to the addition of filter aids. One is to form a layer of the second medium that protects the basic medium of the system. This is commonly referred to as “precoat”. The second objective of filter aids is to improve the flow rate by decreasing cake compressibility and increasing cake permeability. This type of usage is termed “admix” or “body feed”. Filtration without filter aid, with precoat, and with precoat and body feed is shown in the figure below. The particles must be inert, insoluble, incompressible, and irregular-shaped. Common filter aids are diatomaceous earth (Kieselguhr, DE), perlite, cellulose, and others.

(i) Diatomaceous earth: Diatomaceous earth (DE) is the skeleton of ancient diatoms. They are mined from an ancient seabed, processed, and classified to make the different grades of filter aids. DE is the most commonly used filter aid today. However, the crystalline type DE is a suspicious carcinogen and inhalation needs to be avoided during handling. There are different grades of commercial DE. A finer grade may be employed to increase the clarity of filtrate. The smaller the filter aid particle size, the smaller the process particles can be removed. However, the filtration rate is lower. There is always a balance between initial filtrate clarity and filtration rate. The particle size captured by various filter aids may also vary because of liquid viscosity, surface charge, etc.

(ii) Perlite: Perlite is another important mineral filter aid. It is a particular variety of naturally occurring glassy volcanic rock, characterized by onion-like, splintery breakage planes. After crushing and heating, this rock expands in an explosive fashion to about ten times its original volume. Diatomaceous earth and perlite are silica-based minerals.

(iii) Cellulose and others: There are several other special materials used as filter aids, including asbestos, cellulose, agricultural fibers, sawdust, rice hull ash, paper fibers, etc. Cellulose can be used for a filtration system that cannot tolerate silica. The filterability of cellulose is much worse than DE or perlite but cellulose can be incinerated as well as providing better cake integrity. Calcined rice hull ash and fibers from used newspapers are relatively new filter aids. They are used for wastewater sludge dewatering.

Problems in Filtration

There are three major types of filter problems. They can be caused by chemical treatment before the filter, control of filter flow rate, and backwashing of filters.

(i) Chemical addition before filtration

The coagulation and flocculation stages of the water treatment must be monitored continuously. Adjustments in the amount of coagulant added must be made frequently to prevent the filter from becoming overloaded with suspended material. This overload may cause the filter to prematurely reach its maximum head loss. If there is an early turbidity breakthrough in the filter effluent, more coagulants may have to be added to the coagulation process. There may be a need for better mixing during the coagulation or the addition of more filter aid. If there is a rapid increase in filter head loss, too much coagulant may be clogging the filter. Less coagulant or less filter aid should be used.

(ii) Control of filtration flow rate

When a filter is subjected to rapid changes in flow rate it causes filter media to be dirtier. When a feed flow changes, the filter flow also has to change to run the process smoothly. If there is an increase in feed rate, the flow rate should be increased gradually to reduce the impact on the filter. The addition of filter aids may also reduce the impact on the filter medium. This problem can be avoided by keeping one filter in reserve to accept this additional flow. Many plants are not operated continuously, and the start-up at the beginning causes a gush to the filter(s). The filters should be backwashed before putting them back into operation or operated to waste until the effluent meets the standards.

(iii) Backwashing of Filters

Backwashing of the filters is the single most important operation in the maintenance of the filters. If the filter is not backwashed effectively, problems may occur that may be impossible to correct without totally replacing the filter

media. These problems could be caused by improper backwashing procedures.

Theory of filtration