Table of Contents

Construction of triple roller mill

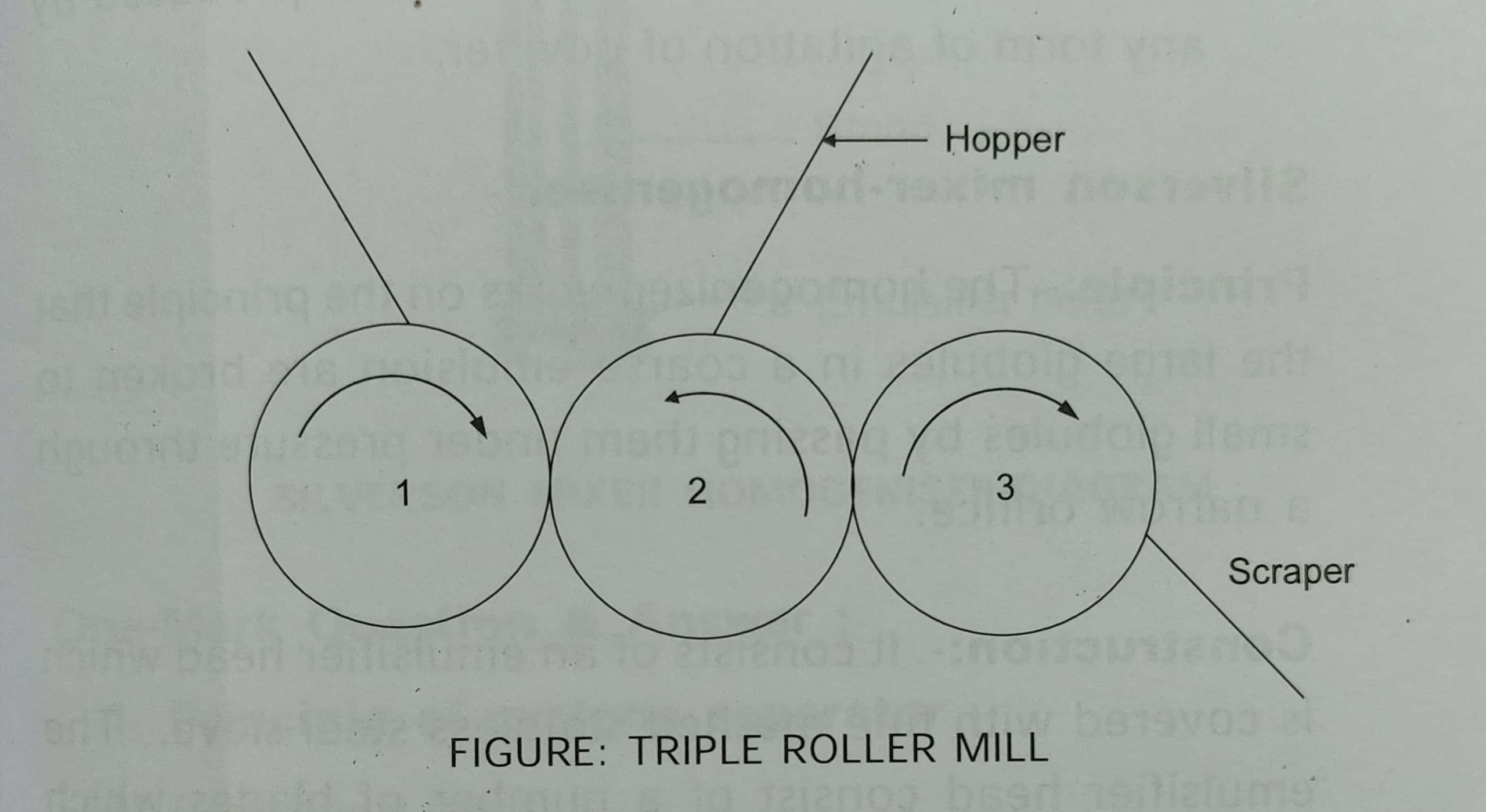

The triple roller mill consists of three rollers which are made of hard abrasion-resistant material. These rollers are arranged in such a way that they come very close to each other. These rollers are rotated at different rates of speed. The material coming between the rollers is crushed depending on the gap between them and the difference in rates of movement of the two surfaces.

Working of triple roller mill

The material after passing through the hopper comes between rollers 1 and 2 and is reduced in size in the process. The gap between roller 2 and 3 is usually less than that between 1 and 2, further crushing and smoothing the mixture which adheres to roller 2. A scraper is arranged in such a way that it can remove the mixed material from roller no. 3 and does not allow the material which has not passed between both sets of rollers to reach the scraper.

Use

It is useful for the purpose of mixing the solid powder in an ointment base.

Also read: Principle Construction, and working of cyclone separator