Most of the chemical and pharmaceutical industries uses a variety of heat transfer equipments. The materials to be heated may be liquids, gases or solids. A heated fluid or condensed steam is used as the heating medium. In pharmacy, operations involved in heat transfer includes preparation of starch paste for granulation, crystallization, evaporation, distillation etc. In industrial processes, heat energy is transferred by various methods. Heat exchangers are the devices used for transferring heat from one fluid (hot gas or steam) to another fluid (liquid) through a metal wall. Heat interchangers are the devices used for transferring heat from one liquid to another or from one gas to another gas through a metal wall. This classification is vague and may time used interchangeably. In a heat interchanger, when heat is transferred the film coefficients on both sides of the tube are of the same order of magnitude. In order to increase the overall coefficient, along with increase in the coefficient on one side the fluid velocity on both sides is also increased to enhance both the coefficients. The fluid velocity and heat transfer coefficient could be achieved by placing baffles outside the tubes. The baffle arrangement increases the path length and decrease the cross-section of the path of the second fluid. Thus, provision of baffles increases the velocity of the liquid outside the tubes and also makes it to flow at right angles to the tubes. It leads to additional turbulence which reduces the resistance for heat transfer outside the tubes.

Baffles

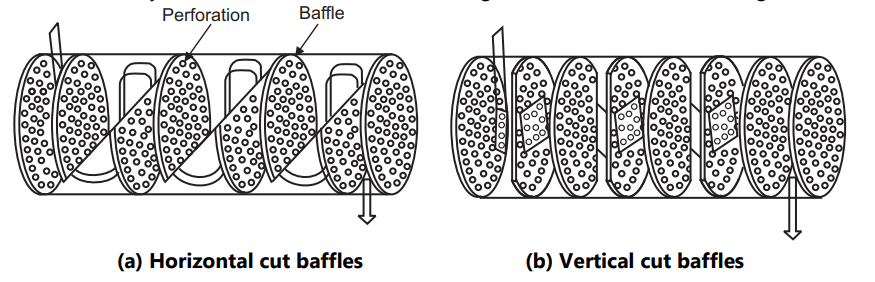

Baffles are metal discs that have one side cut away. These discs are perforated through which tubes are fitted. In order to avoid or at least minimize the leakage, the clearance is kept small between the baffles, shell, and tubes. The baffles are supported on metal rods and are fastened between the tube sheets by set-screws. Baffles are used to boost the shell side heat transfer coefficient by creating turbulence in the shell side fluid by modifying the flow pattern parallel or cross flow to the tube bundles. It also has a function to support the tube all along its length otherwise the tube may bend. Moreover, these baffles may have horizontal or vertical cuts (segmental baffle) as shown in Figure below.

The cut portion of the baffle is called as baffle window. It provides the area for flow of the shell fluid. The baffle window area ranges from 15% to 50%. At 20% cut segmental baffle means that the area of the cut-out portion is 20% of the area of the baffle. The spacing between the baffles has significance in terms of pressure drop and heat transfer coefficient. A larger spacing reduces the shell side pressure drop, decreases turbulence and heat transfer coefficient. A smaller spacing increases the turbulence and heat transfer coefficient but the pressure drop may increase significantly, thus the advantage attained due to the higher heat transfer coefficient may be nullified. Thus, baffle spacing is selected based on the allowable shell side pressure drop and the desired heat transfer coefficient. Generally, the minimum spacing of segmental baffles is 1/5th of the shell diameter.

Make sure check our amazing article on: Heat exchangers