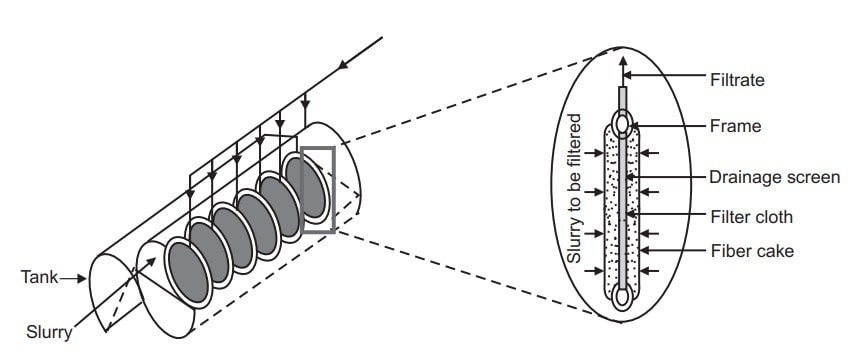

The filter leaf is the simplest form of filter, consisting of a frame that encloses a drainage screen or grooved plate and the whole unit being covered with a filter cloth. The outlet for the filtrate connects to the inside of the frame. The frame used may be circular, square, or rectangular in shape. There are two types of filter leaf namely; vertical and horizontal.

Table of Contents

Construction for Filter Leaf

The filter leaf is a versatile piece of equipment. The slurry is pumped under pressure into a vessel that is fitted with a stack of vertical leaves that serve as filter elements. Each leaf has a centrally located neck at its bottom which is inserted into a manifold that collects the filtrate. The leaf is constructed with ribs on both sides to allow free flow of filtrate towards the neck and is covered with coarse mesh screens that support the finer woven metal screens or filter cloth that retain the cake, shown in Figure below. (enlarged section).

The space between the leaves may vary from 30-100 mm depending on the cake formation properties and the ability of the vacuum to hold a thick and heavy cake to the vertical leaf surface. The space is set by the filtrate necks of the leaves at the bottom end and with spacers at the top end brackets. For fast filtering slurries, the space may be doubled by removing every second plate so consequently the cake space doubles but the filtration area is reduced to half.

The Vessel

There are two types of vessel configuration, namely vertical vessels and horizontal vessels. The leaves inside horizontal tanks, as shown in Figure 1, may be positioned either along the tank axis or perpendicular to the axis. The leaves are graduated to fit to the circular contour of the tank to reduce the slurry heel volume that surrounds the leaves. The vessels are fitted with highly secured cake discharge openings to ensure the safe sealing of the tank under pressure. For wet cakes, the vessel normally has a small outlet fitted with a valve while for dry cakes the opening is large and the closure locks up electrically or hydraulically with a bayonet wedge. The head cover of vertical vessels is often pivoted to swung away to allow the upwards removal of the leaves in the stack. In vertical leaf filter cakes depart easily while in horizontal leaf filter it is necessary to incorporate means to assist discharge. For such cakes that do not discharge readily a special mechanism that vibrates the entire stack such as oscillating high impact jet headers is provided. The headers also serve to wash the filtering medium and dislodge particles that clog the metal screen or cloth. The largest leaf filters in horizontal vessels have a filtration area of 300 m2 and in vertical vessels is 100 m2 , both designed for an operating pressure of 6 bars.

Selection Criteria

Vertical leaf filters are best selected when minimum floor space for large filtration areas is required. If, the liquids are volatile and may not be subjected to vacuum, there is a risk of environmental hazard from toxic, flammable or volatile cakes, high filtrate clarity is required for polishing applications, handling saturated brines that require elevated temperatures the tank may be steam jacketed and the cake may be discharged either dry or as a thickened slurry. They should be selected with care if, the cake is thick and heavy and the pressure is not sufficient to hold it on the leaf. Coarse mesh screens are used and the filtration step must be preceded with a precoat to retain cakes with fine particles. The precoating with a thin layer of diatomite or perlite is not a simple operation and should be avoided whenever possible.

Working for Filter Leaf

The operation of a vertical pressure leaf filter is labour intensive and requires a complex manipulation of valves so installations are in most cases fully automated.

(i) Precoating: The precoating stage is done when the contaminants are gelatinous and sticky and the precoat layer forms a barrier that avoids cloth blinding. Likewise, the interface between the precoat and the cloth departs readily so the cake discharges leaving a clean cloth. In addition, it is done when a clear filtrate is required immediately after the filtration cycle commences otherwise recirculation must be employed until a clear filtrate is obtained.

(ii) Filtration: Once the precoating stage is completed the process slurry is pumped into the filter, the forming cake is retained on the leaves and the filtrate flows to further processing. When the solids are fine and slow to filter, a filter-aid is added to the feed slurry in order to enhance cake permeability. The addition of filter-aid increases the solids concentration in the feed so it occupies additional volume between the leaves and increases the amount of cake for disposal. Similarly, for all those applications when the cake is the product, precoat and filter-aid may not be used since they mix and discharge together with the cake.

(iii) Heel Removal: Once the filtration cycle is completed air or gas is blown into the vessel and the slurry heel that surrounds the leaves is pushed and displaced downwards until it reaches the lowest part of the leaf stack. At this point, the remaining heel slurry is evacuated back to the feed tank by a special dip pipe that is located at the very bottom of the vessel so that the vessel is empty from the slurry.

(iv) Cake Drying: The air then continues to pass through the cake until the captive moisture is reduced to a minimum and the cake is in practical terms considered to be dry.

(v) Cake Discharge: At this stage, the air pressure is released, the cake outlet is opened and the leaf stack is vibrated to discharge the cake. The cake outlet opening must be interlocked with a pressure sensor to avoid opening under pressure. On some filters, the cloth or mesh screen may be backwashed with water after cake discharge to dislodge and remove any cake residue that is adhered to the medium.

Advantages for Filter Leaf

(i) The cloth or woven mesh screens that cover the leaves of horizontal tanks may be accessed easily once the stack is pulled out of the vessel.

(ii) If there are cake bridges between the leaves manually washing the medium with high impact jets is possible.

(iii) Filter leaf is mechanically simple since there are no complex components in it.

(iv) The method has the advantage that the slurry can be filtered from any vessel and the cake can be washed simply by immersing the filter, in a vessel of water.

(v) A number of leaves can be connected to provide a larger area for filtration.

(vi) Labour costs for operating the filter are comparatively moderate.

(vii) The special feature of the leaf filter is the high efficiency of washing.

Disadvantages

(i) High headroom is required for dismantling the leaves on vertical vessels.

(ii) Large floor space is required for discharging the cake on horizontal vessels.

(iii) The emptying of the vessel in between cake filtration, washing, and drying requires close monitoring of the pressure inside the vessel to ensure that the cake holds on to the candles.

(iv) The operation of a vertical pressure leaf filter is labour intensive and requires a complex manipulation of valves.

Applications

(i) The vertical pressure leaf filter is used for the polishing slurries with very low solid content of 1- 5% or for cake filtration with a solid concentration of 20 – 25%.

(ii) The vertical leaf filters are suitable for handling flammable, toxic, and corrosive materials since they are autoclaved and designed for hazardous environments when high pressure and safe operation are required.

(iii) The vertical leaf filters may be readily jacketed for applications whenever hot or cold temperatures are to be maintained.

Also read: Equipment used in the filtration process