Elutriation Tank: An elutriator is a straightforward device that divides particles into two or more groups. Elutriation occurs when a fluid moves in the opposite direction of particle sedimentation. Particle size, shape, and density all play a role in elutriation. The air elutriator is mostly utilized for particles with a diameter of less than 1 m. Because their terminal sedimentation velocities are lower than the rising fluid’s, the smaller or lighter particles climb to the top (overflow). If the particle’s Reynolds number is less than 0.2, Stokes’ law can be used to compute the terminal velocity of any particle in any medium. The separation of particles in an elutriator is based on their densities. The gravitational force causes the heavier particles to settle.

Table of Contents

Principle of Elutriation Tank

Particles falling in a rising fluid can be categorized into two sizes during the elutriation process. When the fluid in a sorting column rises at a certain velocity, the particles with higher terminal velocities settle at the bottom of the column, while the particles with lower terminal velocities are lifted to the top of the column and moved away to the next tube. The Stokes’ law equation for Reynolds number can be used to compute the terminal velocities of particles falling in a fluid.

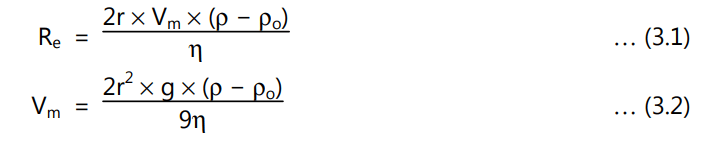

Where, ρ = specific gravity of the particle, ρo specific gravity of the fluid medium, r is radius of the particle, η = viscosity of the medium, Vm = terminal velocity of the particle, and g = gravitational acceleration.

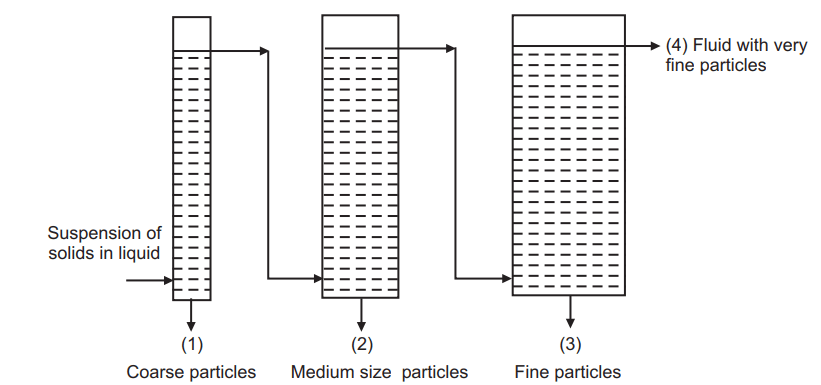

When the volumetric flow rate of rising fluid is constant throughout elutriation, the velocity of the rising fluid in the columns is determined by their diameters. The narrow diameter column gives high velocity and the one with wide diameter gives low fluid velocity. Higher velocities of the rising medium allow coarser particles to settle while lower velocities allow finer particles to settle. Various size classes of particles can be obtained when the sample is separated in columns of increasing diameters connected in series. The upper size limit of the particles follows Stokes’ law.

Construction of Elutriation Tank

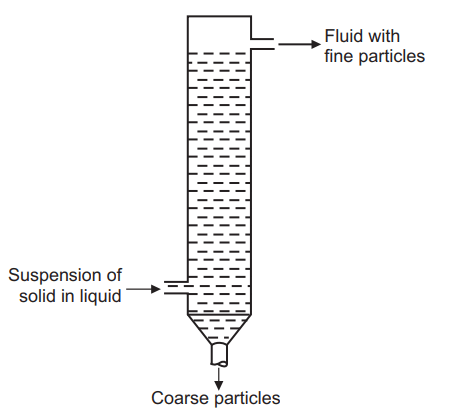

The apparatus for the gravity system is essentially a vertical column with a suspension intake near the bottom, a coarse particle outlet near the base, and a fluid overflow near the top, as shown in Fig. 3.8. One column will give a single separation into two fractions, but keep in mind that there will be a velocity gradient across the tube, resulting in the separation of particles of different sizes based on their distance from the wall. If more than one fraction is needed, a sequence of tubes with the increasing cross-sectional area can be connected, as shown in Figure 3.9.

With the same overall flow rate, the velocity will decrease in succeeding tubes as the area of cross-section increases, giving a number of fractions.

Working of Elutriation Tank

The material whose particles are to be separated is first levigated and the paste is transferred to elutriation tank. A large amount of water is added to tank so as to make independent particle settling. The contents in the tank are stirred to obtain uniform particle distribution. If left aside undisturbed coarse particles settle at the bottom where as small size particles remain suspended in liquid. These fines can be transferred to next elutriator in connection wherein similar process of separation takes place to obtain further fractions of fines.

Merits

- The process is continuous.

- The separation is quicker than with sedimentation.

- It has feasibility to add many columns based upon fractions required.

- It needs no skilled operators.

- It is a fast process than sedimentation.

Demerits

- The suspension has to be dilute; which may sometimes be undesirable.

- It separates particles based on their sedimentation property but not on specific features (for example, surface or shape).

- It cannot separate different types of particles which have similar sedimentation properties.

Applications of Elutriation Tank

- Following a size reduction process, both simple and multiple elutriators are employed for comparable reasons, with the goal of separating large particles, which may be returned for additional grinding, used for other purposes, or discarded depending on the conditions.

- With liquids, it can be used to separate insoluble solids, such as kaolin or chalk, which are often subjected to wet grinding followed by sedimentation or elutriation with water.

- With gases, it can be applicable to finer solids that would separate too slowly in liquids, to water-soluble substances, or where dry processing is required.

Make sure Check our Amazing article on: Air Separator