Table of Contents

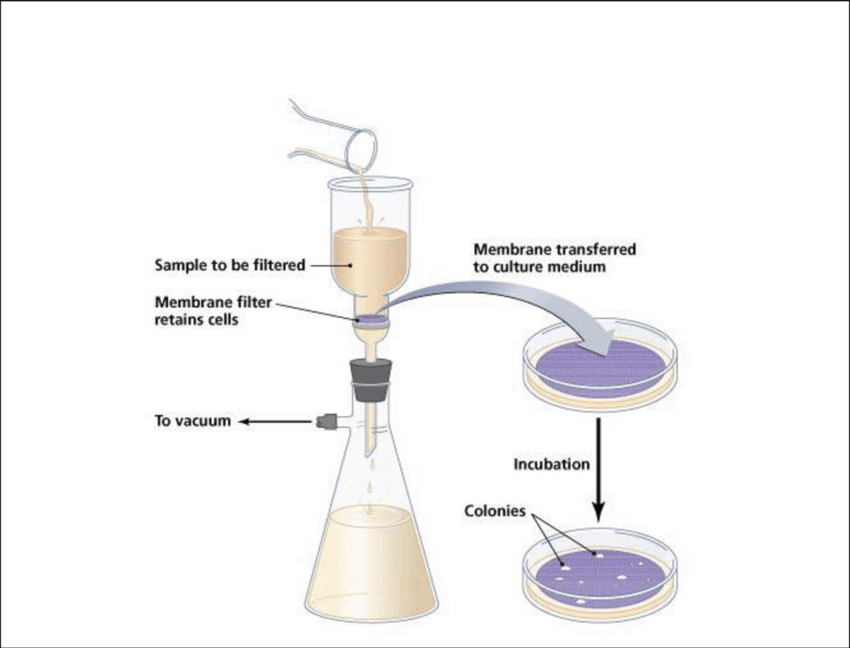

Principle of Membrane filter:

Membrane filter: (Microfiltration) Fitter the material that can retain large solid particles and other particles liquid passes through a microporous membrane material to separate specific substances under the action of static pressure difference.

Construction Membrane filter:

Membrane filters are made of thin and flat membranes of cellulose derivates, (eg: cellulose acetate, and cellulose nitrate). These filters are brittle when it is stored in dry conditions. The filters are 50-150m thickness, and available in sizes up to 60cm². It has 400-500 million pores per square centimeter of filter surface.

Working:

The membrane filter pores are uniform in size and occupy about 80% of the filter volume to avoid clogging the membrane, pre-filtration is often required. The selection of membrane filter depends upon the particles to be removed.

Eg: 0.2m for filtering of all bacteria. 1.2μ for filtering non-living particles.

Uses:

These filters are used for the sterilization of both aqueous and oily liquids.

Also read: Principle Construction, and working of cyclone separator