Table of Contents

What are Aerosols?

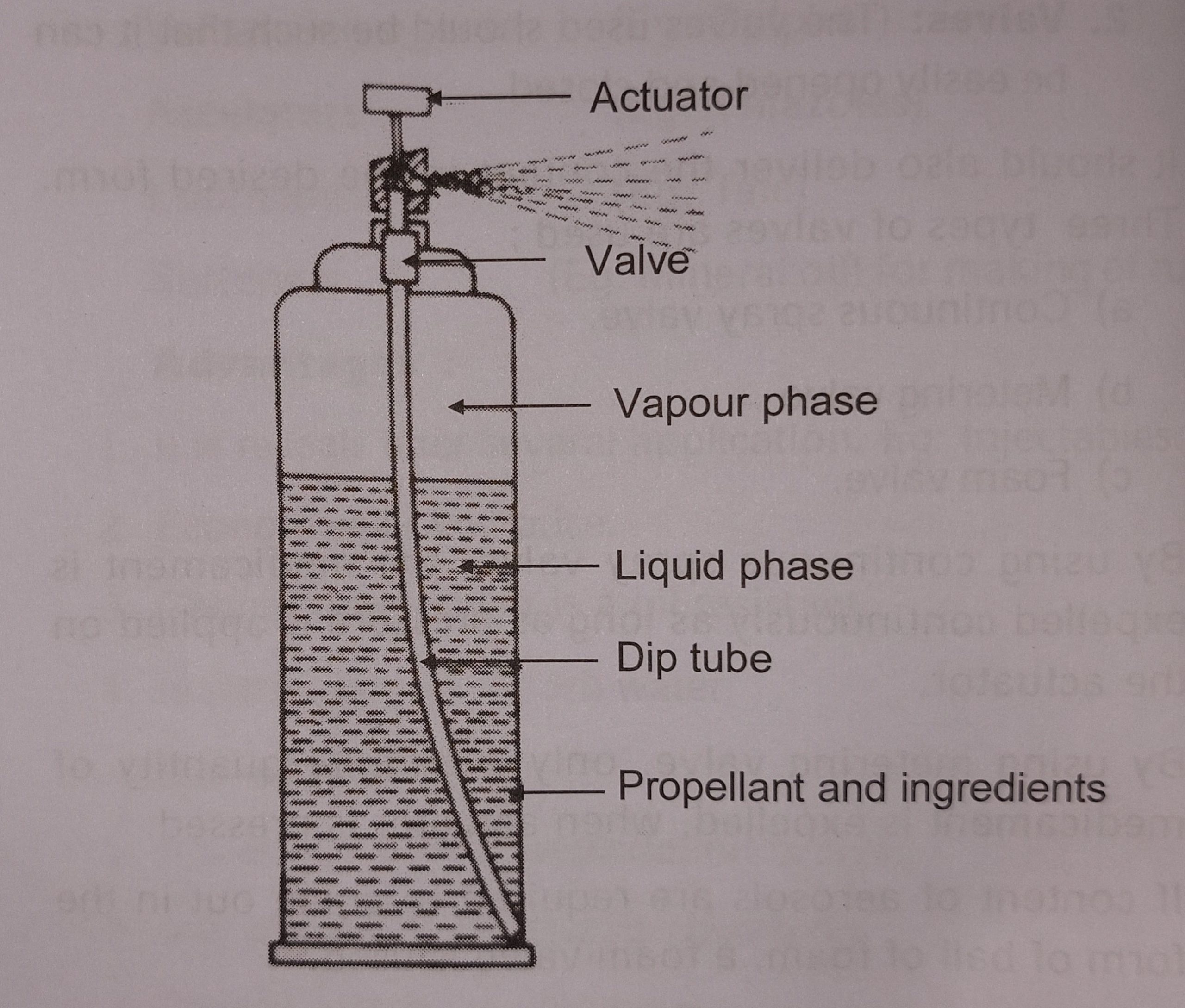

Aerosol may be defined as a dispersed phase system, in which very fine solid particles or liquid droplets get dispersed in the gas, which acts as a continuous phase. These are also called pressurized dosage forms.

Containers used for Aerosol:

The aerosol container can be divided into 4 parts,

- Container: In pharmaceutical aerosol packaging, the containers are made from metal, glass, and plastic. These containers can withstand high pressure.

- Valves: The valves used should be such that it can be easily opened and closed. It should also deliver the content in the desired form. Three types of valves are used;

- Continuous spray valve.

- Metering valve

- Foam valve.

By using a continuous spray valve, the medicament is expelled continuously as long as pressure is applied to the actuator.

By using the metering valve, only a definite quantity of medicament is expelled, when the actuator is pressed.

If the content of aerosols is required to come out in the form of a ball of foam, a foam valve is used.

3. Actuator: The actuator is fitted on the valve stem. It helps in the easy opening and closing of the valve, whenever it is required. There are various types of actuators that can produce spray, fine mist, or foam.

4. Dip tubes: Dip tubes are made from polyethylene or polypropylene.

The dip tube is used to prevent the propellant to come out without dispensing the contents of the package.

It conveys the liquid from the bottom of the container to the valve at the top. The dip tube should be extended almost to the bottom of the container.

Advantages and disadvantages of aerosol packing

Aerosol Packaging: Aerosols may be defined as a dispersed phase system in which very fine solid particles or liquid droplets get dispersed in the gas which acts as a continuous phase. These are also called pressurized dosage forms

Advantages :

- The medicament can be delivered directly to the affected area.

- The absence of air prevents the oxidation of the product.

- The hydrolysis of medicament prevented.

- The applications of medicament are easier.

- The fine mist is easily formed for inhalation purposes.

- Drugs can be given by oral inhalation

- The sterility of the product can be maintained. 8. Manual contact with medicaments can be avoided.

- The chances of decomposition of drugs in G.I.T are less.

Disadvantage:

- Aerosol is costly preparation.

- Some of the propellants are very toxic.

- The cooling effect of highly volatile propellants may cause discomfort on injured skin.

- A lot of difficulties are faced in aerosol formulation when the drug is not soluble in the propellant.

Also read: Different types of metals are used in the pharmaceutical industry.