The mechanism of size reduction depends upon the nature of the material, and each material requires different treatment. Fracture generally occurs along the lines of weakness. During size reduction, fresh surfaces are created or existing cracks and fissures are opened up, wherein the former requires more energy. There may be a tendency that after processing, agglomerates of particles are formed. Size reduction is an energy-inefficient process because a small amount of energy is required to subdivide the particles. A lot of the energy is spent overcoming the friction and inertia of machine parts and the friction between particles and deforming the particles without breaking them. This energy is released as heat.

Table of Contents

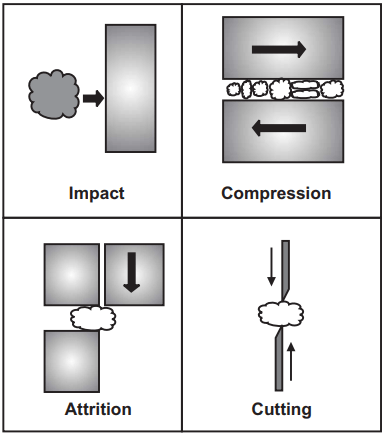

Compression

In this mechanism, the material is crushed by the application of pressure. Compressive forces are used for the coarse crushing of hard materials. Coarse crushing implies reduction to a size of about 3 mm.

Impact

When a substance is more or less immobile and is struck by a fast-moving object, or when a moving particle collides with a stationary surface, impact occurs. The material is crushed in both cases into smaller pieces. Because the substance is hit by a moving hammer and the particles created are subsequently hurled against the machine’s shell, both of these things usually happen. Impact forces are general-purpose forces that can be found in the coarse, medium and fine grinding of a wide range of materials.

Attrition

Attrition applies pressure to the material in the same way compression does, but the surfaces move relative to each other, resulting in shear forces that break the particles. When the size of the products can reach the micrometre range, shear or attrition forces are used in fine pulverization. Ultra-fine grinding is a phrase that is sometimes used to describe procedures that produce particles in the sub-micron range.

Cutting

Cutting lowers the size of solid materials by separating them into smaller particles via mechanical action (sharp blade/s). Cutting is a technique for breaking down big chunks of material into smaller bits with a defined shape that can be processed further, such as powders and granules.

Make sure check our amazing article: Applications of size reduction